Metals 12.1 to 12.4

12.1 Properties of metals

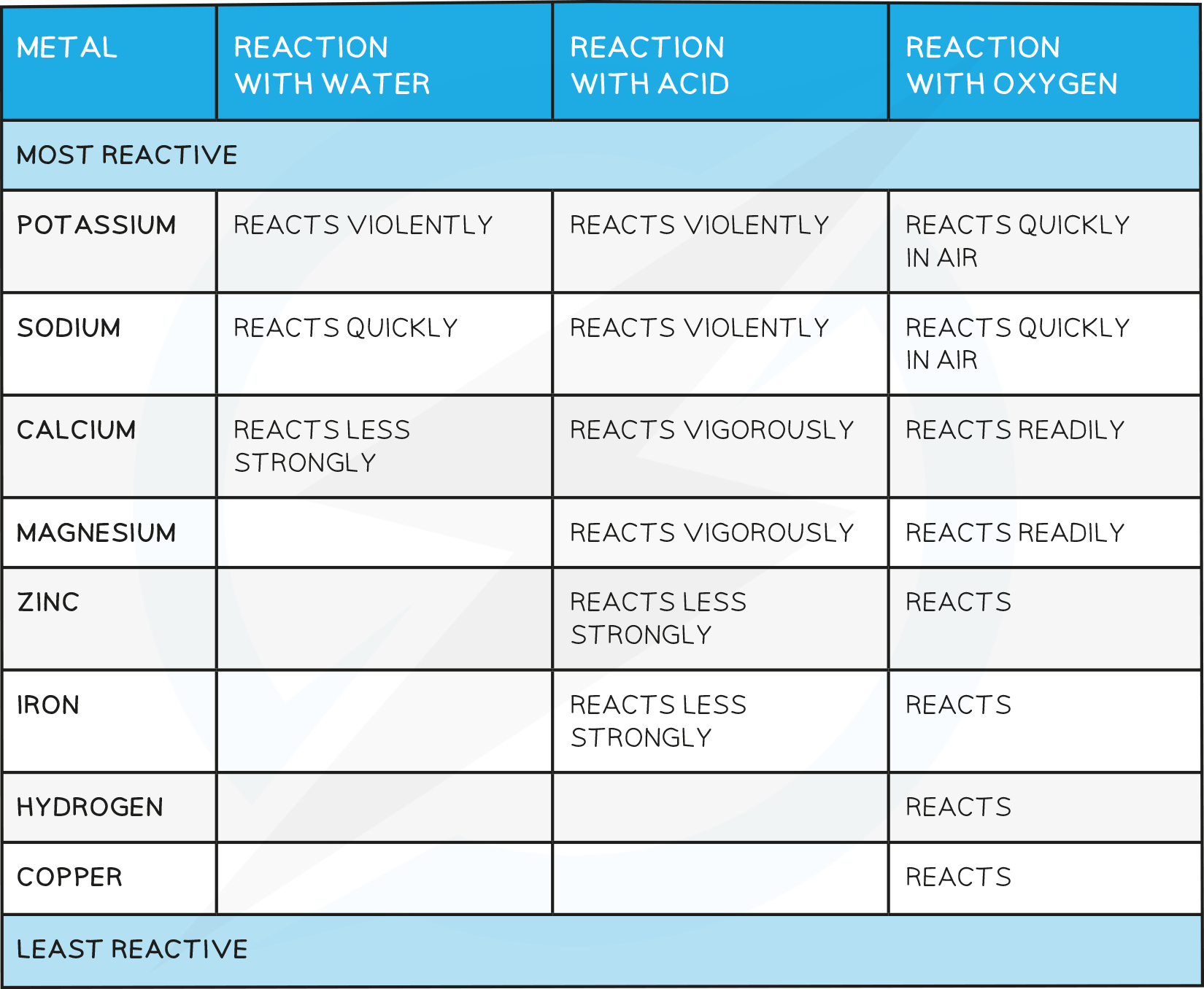

General Chemical Properties

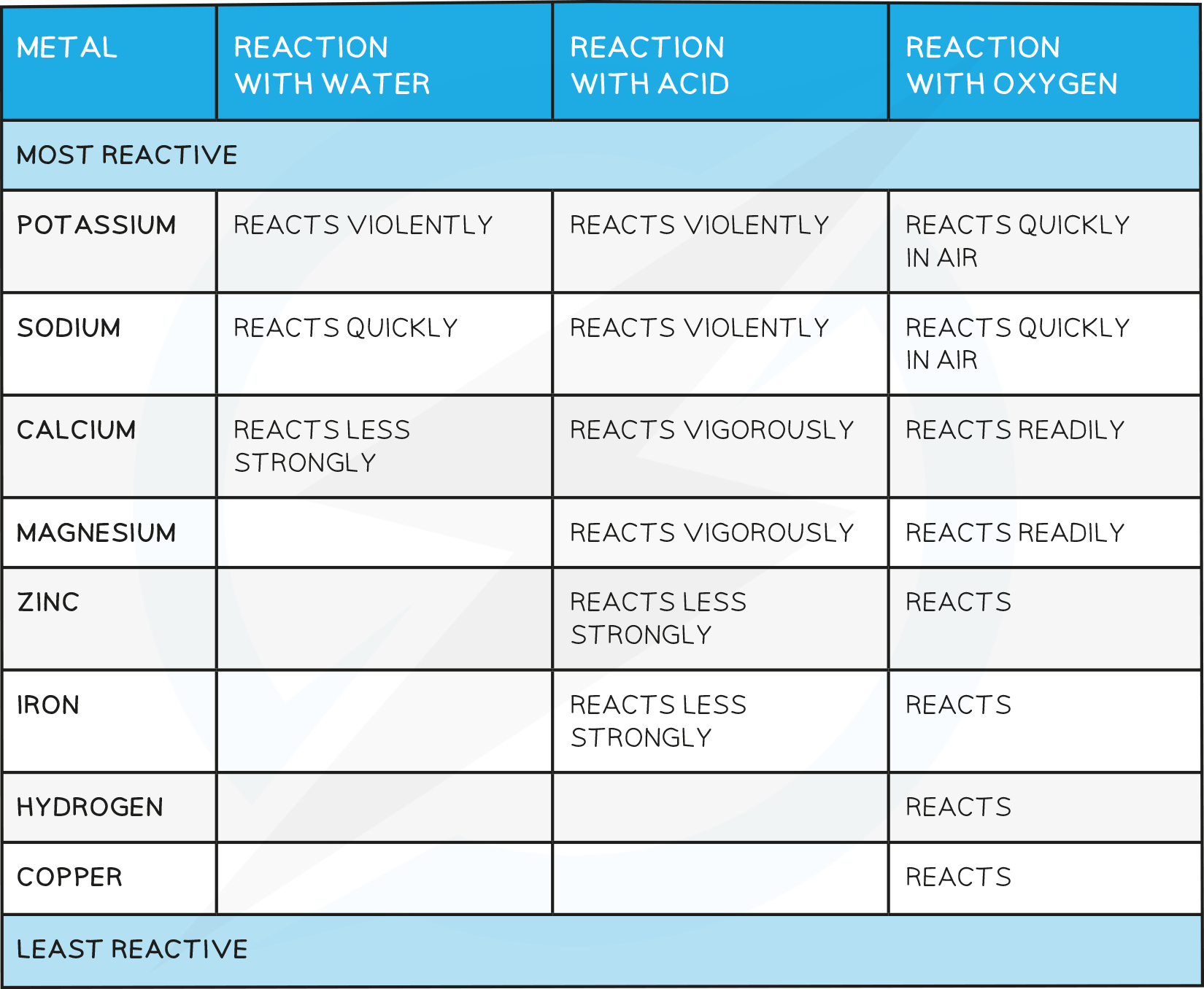

The chemistry of metals is studied by analysing their reactions with water, dilute acid and oxygen

Based on these reactions, a reactivity series of metals can be produced

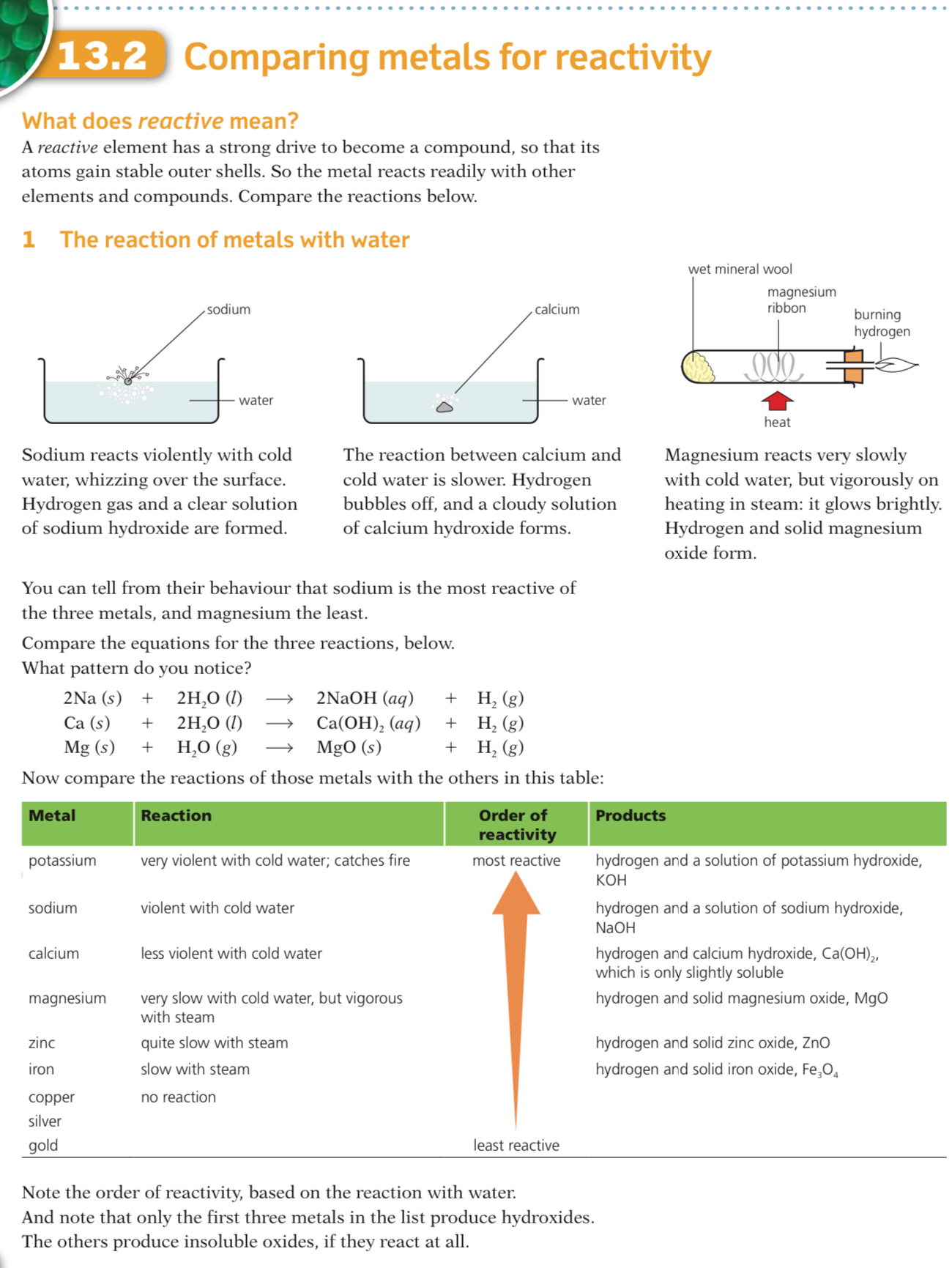

Reactivity with water

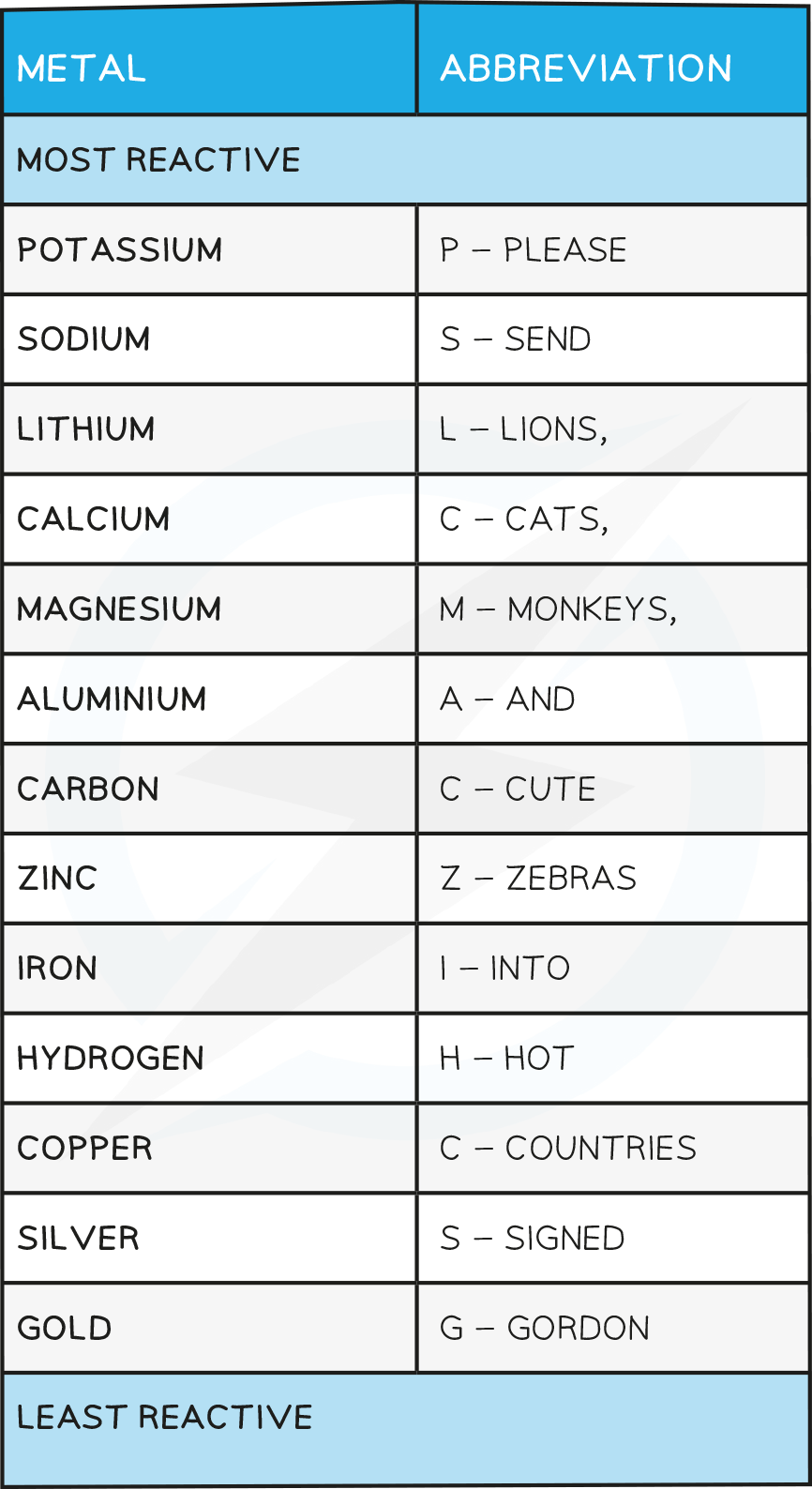

Some metals react with water, either warm or cold, or with steam

Metals that react with cold water form a metal hydroxide and hydrogen gas

metal + water → metal hydroxide + hydrogen

For example calcium:

Ca (s) + 2H2O (l) → Ca(OH)2 (aq) + H2 (g)

Metals that react with steam form metal oxide and hydrogen gas, for example zinc:

Zn (s) + H2O (l) → ZnO (s) + H2 (g)

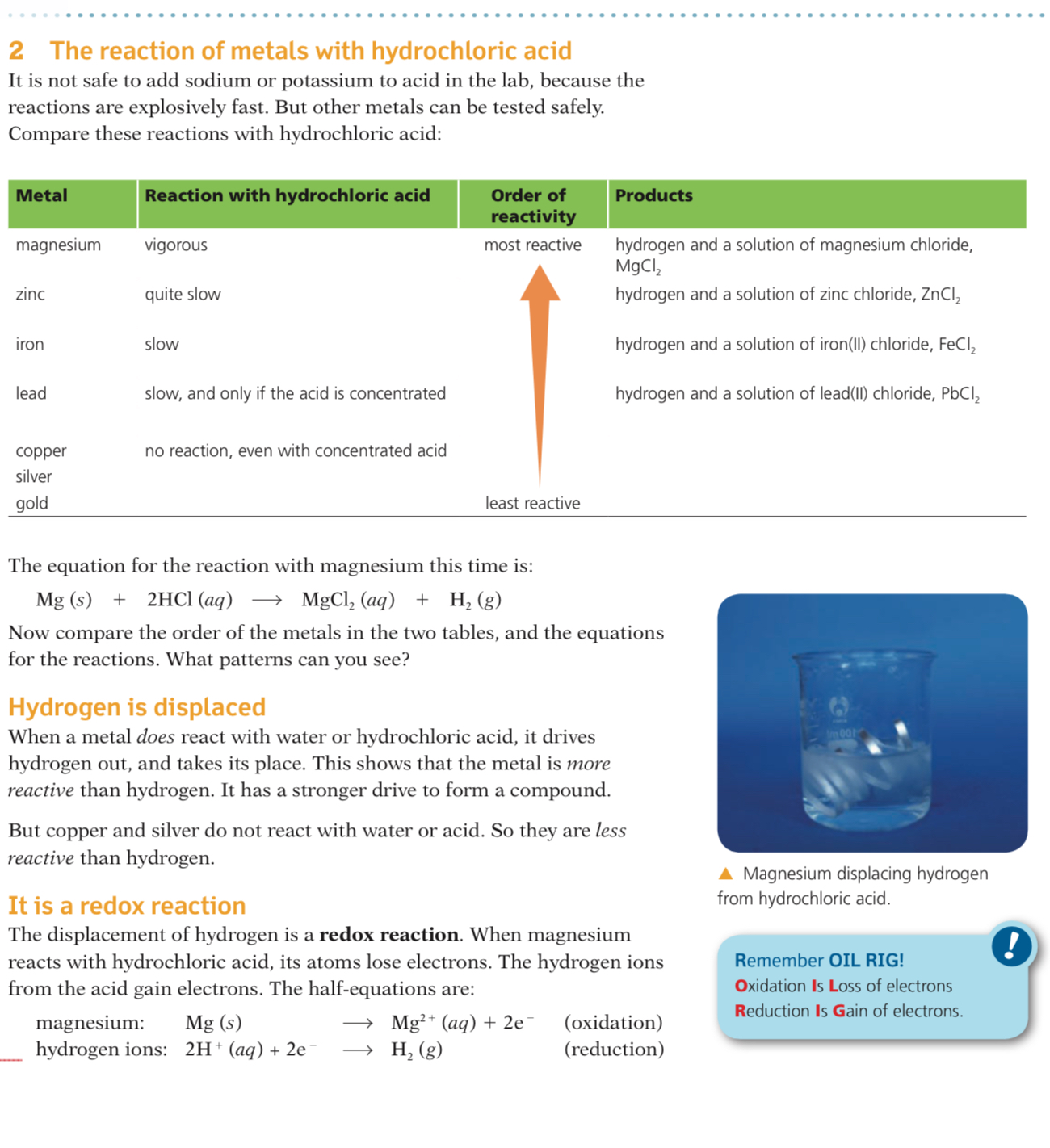

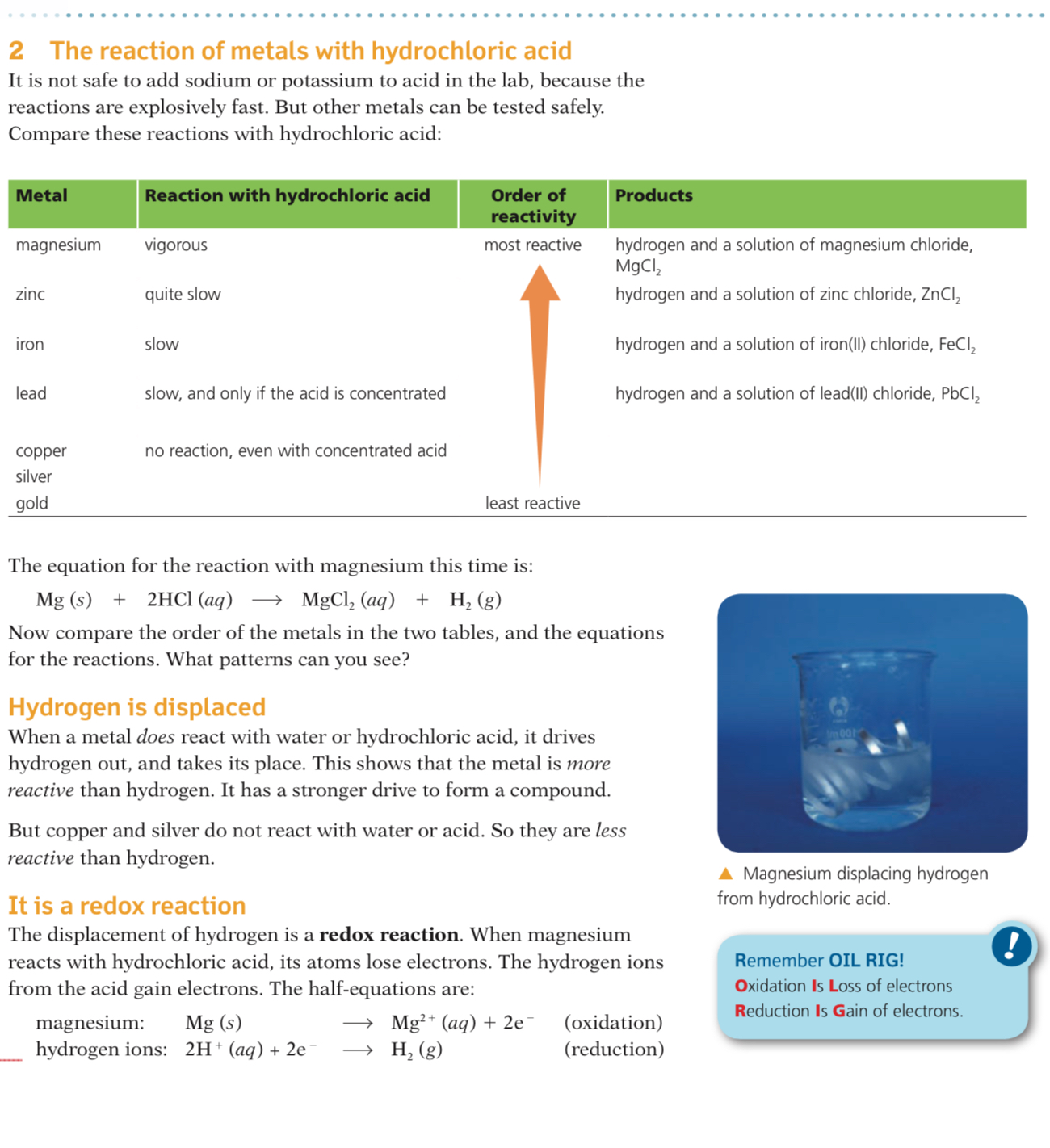

Reactivity with acids

Most metals react with dilute acids such as HCl

When acids and metals react, the hydrogen atom in the acid is replaced by the metal atom to produce a salt and hydrogen gas, for example iron:

metal + acid → salt + hydrogen

Fe (s) + 2HCl (aq) → FeCl2 (aq) + H2 (g)

Reactivity with oxygen

Unreactive metals such as gold and copper do not react with acids

Some reactive metals such as the alkali metals react easily with oxygen

Copper and iron can also react with oxygen although much more slowly

When metals react with oxygen a metal oxide is formed, for example copper:

metal + oxygen → metal oxide

2Cu (s) + O2 (g) → 2CuO (s)

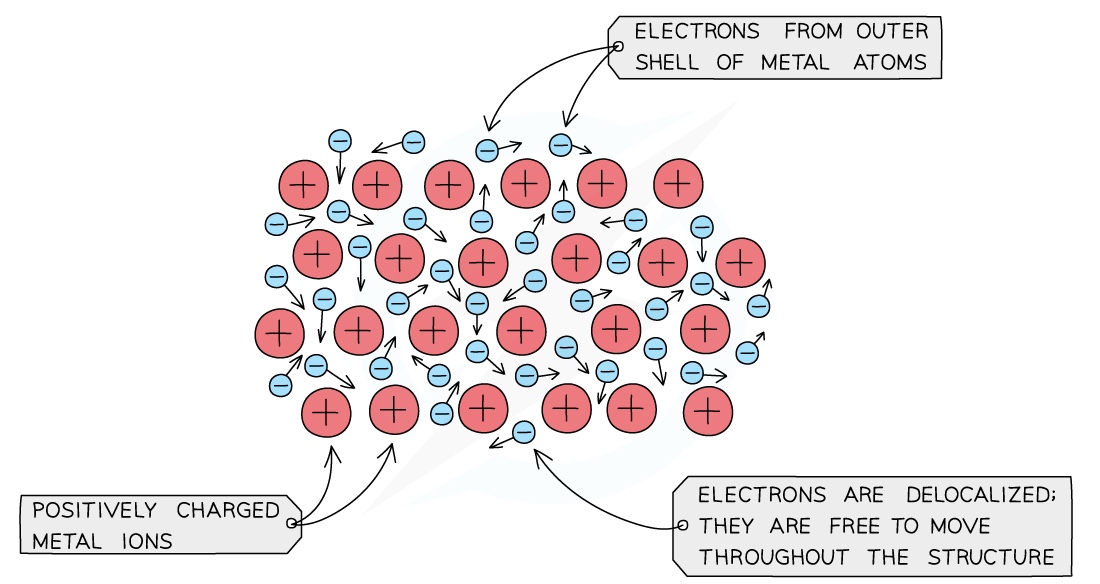

Typical physical properties of metals :

high melting points.

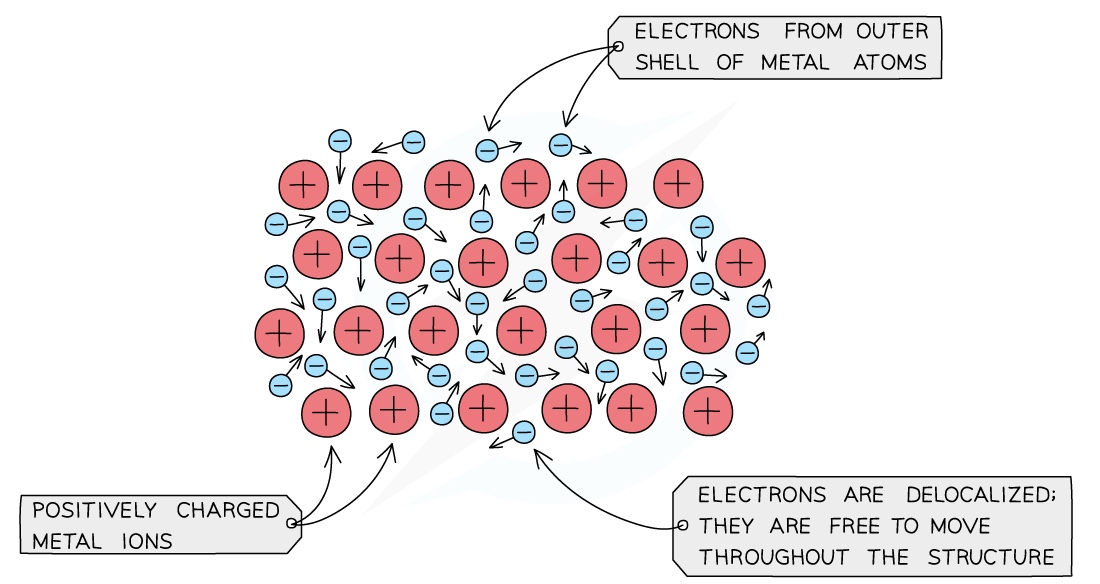

good conductors of electricity.

good conductors of heat.

high density.

malleable.

ductile.

Chemical Properties of Metals

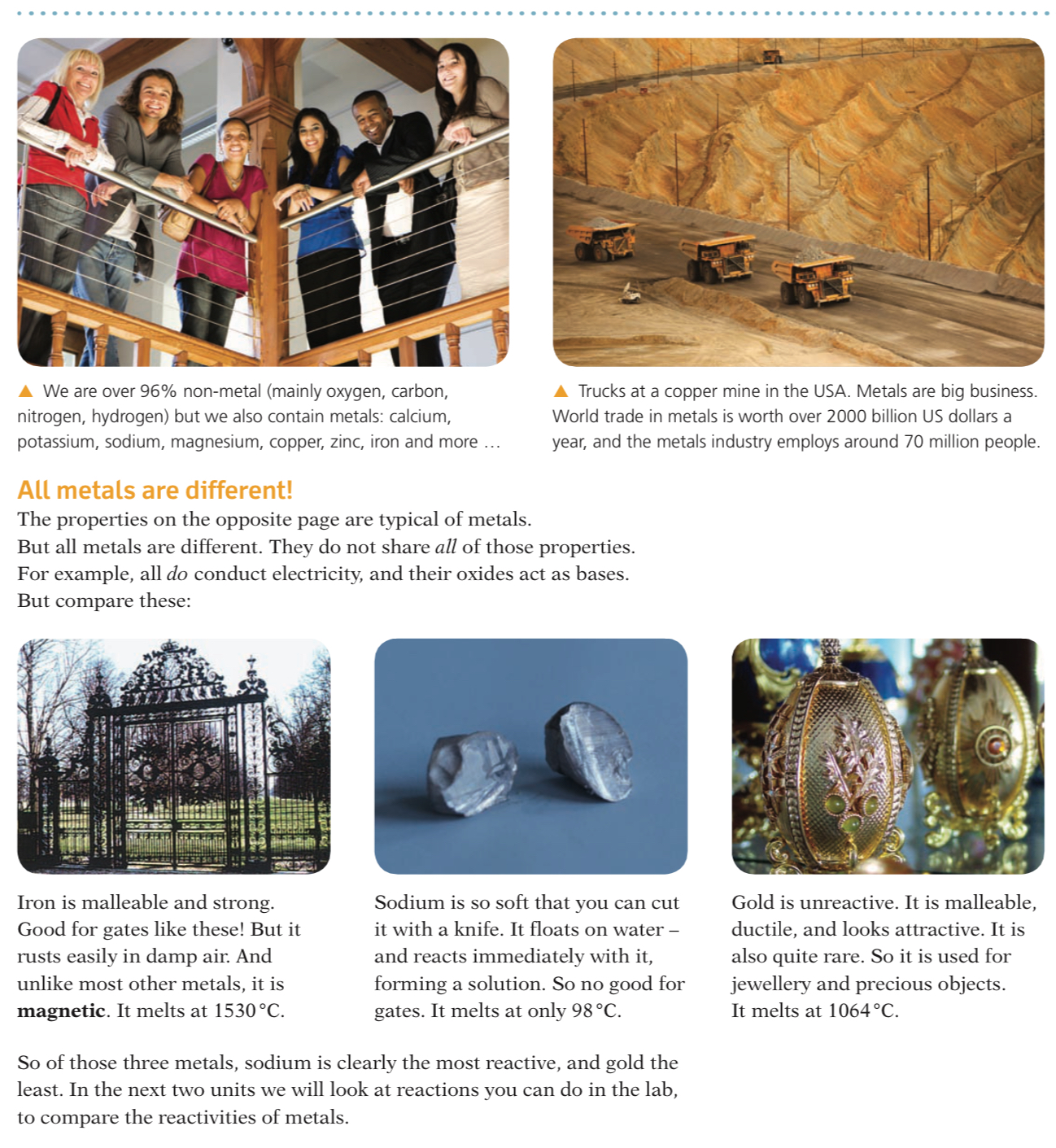

The density of metals is usually high.

Metals are malleable and ductile.

Metals form an alloy with other metals or non – metals.

Some metals react with air and corrode. ...

Metals are good conductors of heat and electricity. ...

Generally, metals are in a solid state at room temperature

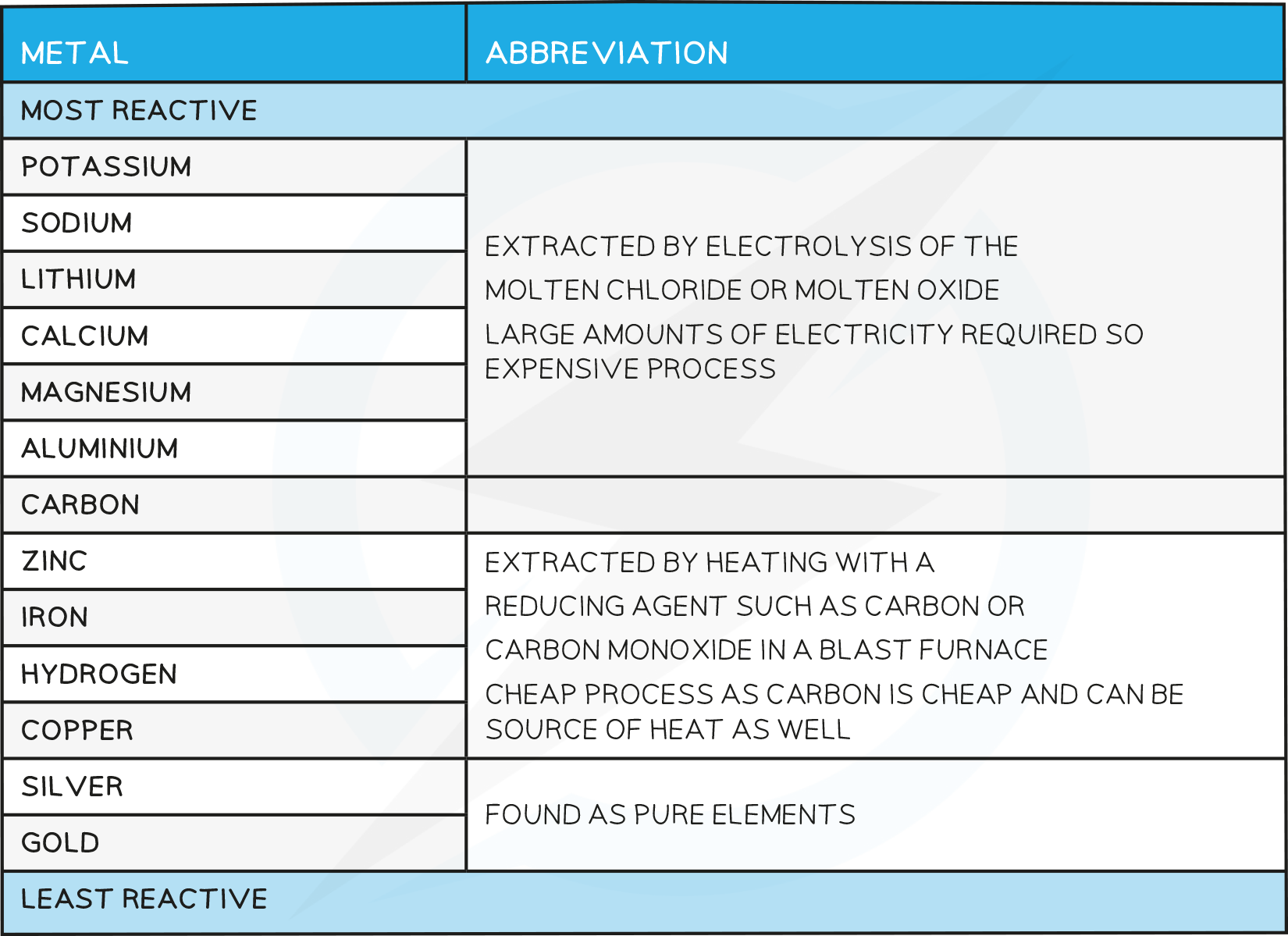

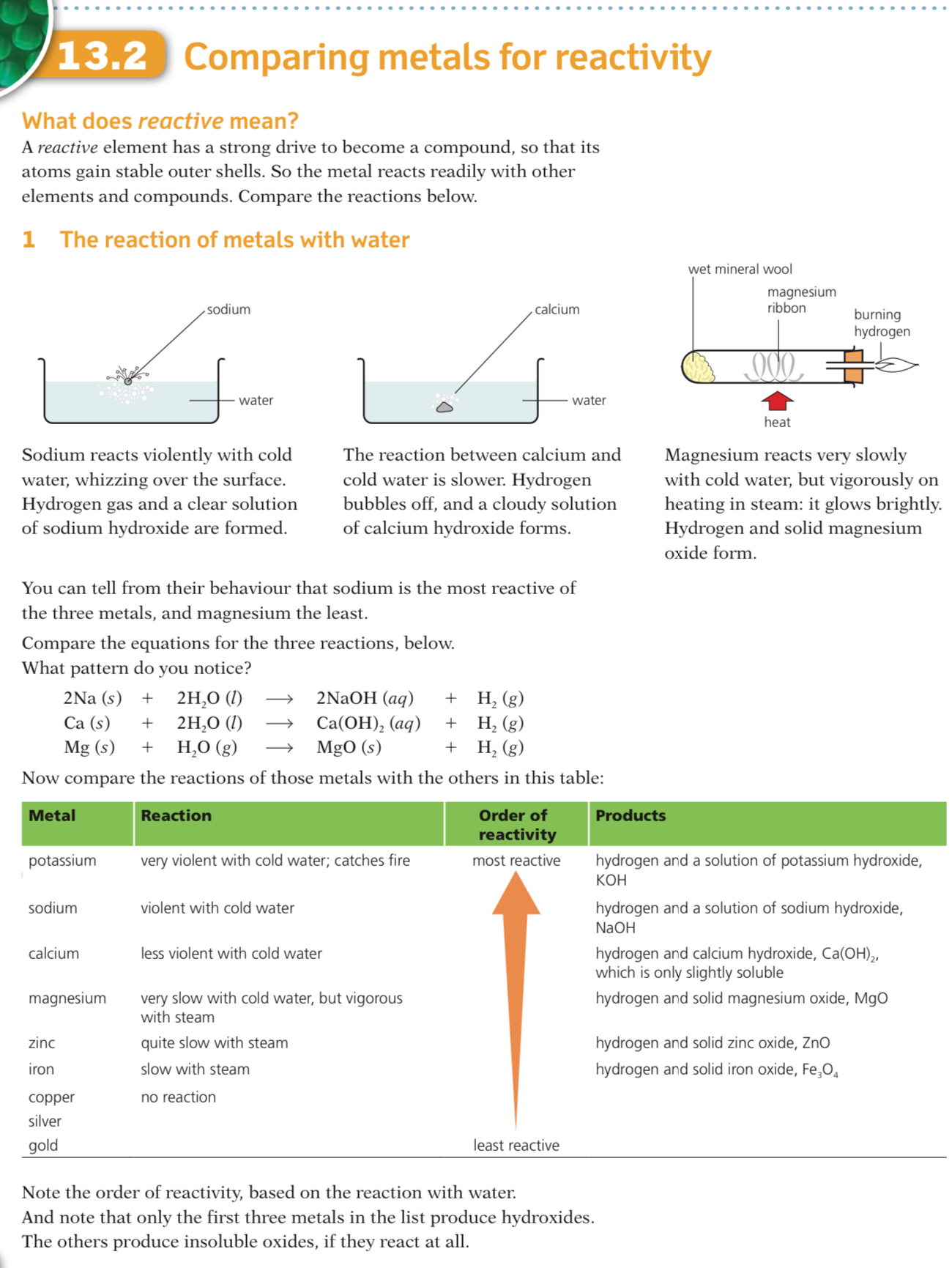

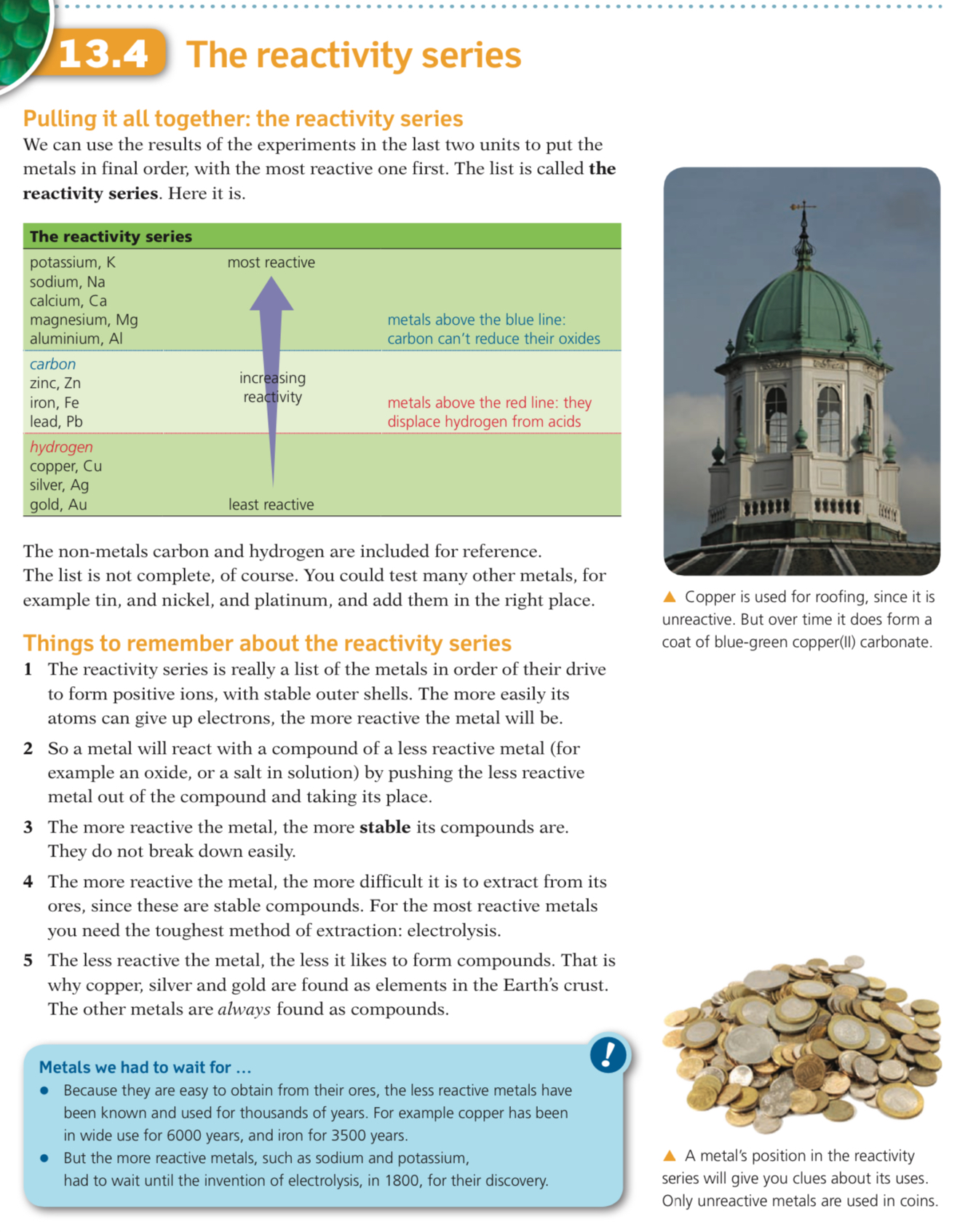

12.2 The Reactivity Series

Based on how metals react with water, dilute acid and oxygen, a reactivity series of metals can be produced

Reactivity of a metal is determined by its tendency to lose electrons and form positive ions

If a metal loses electrons easily it is more reactive than a metal that loses them less easily

The non-metal carbon is also included in the reactivity series as it is used to extract metals from their oxides

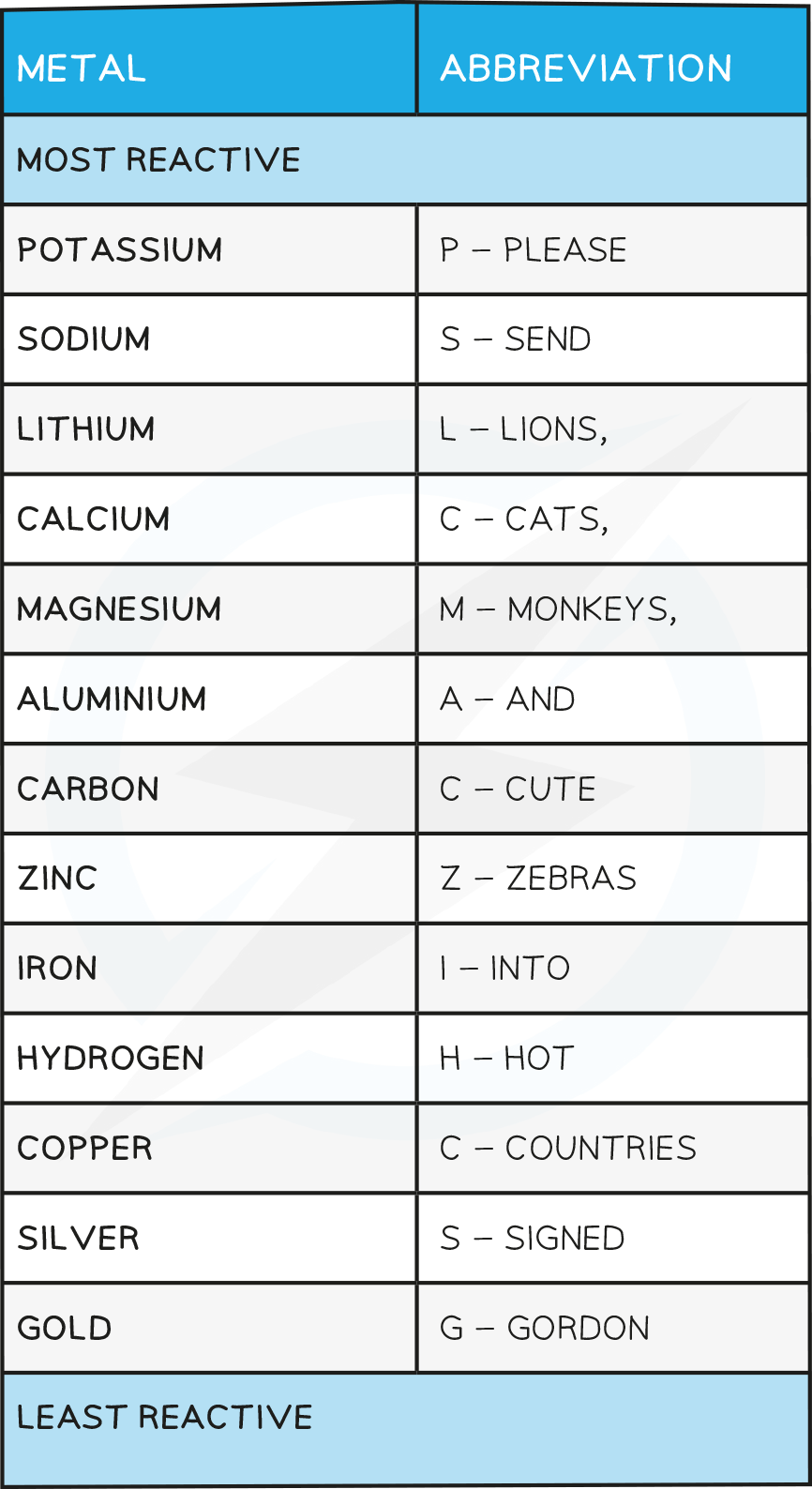

it’s important to learn The Reactivity series here’s a nemonic to help

Observations from the table above allow the following reactivity series to be deduced

The order of this reactivity series can be memorised using the following mnemonic

“Please send lions, cats, monkeys and cute zebras into hot countries signed Gordon

12.3 Extraction of Metals

Obtaining metals from there ores

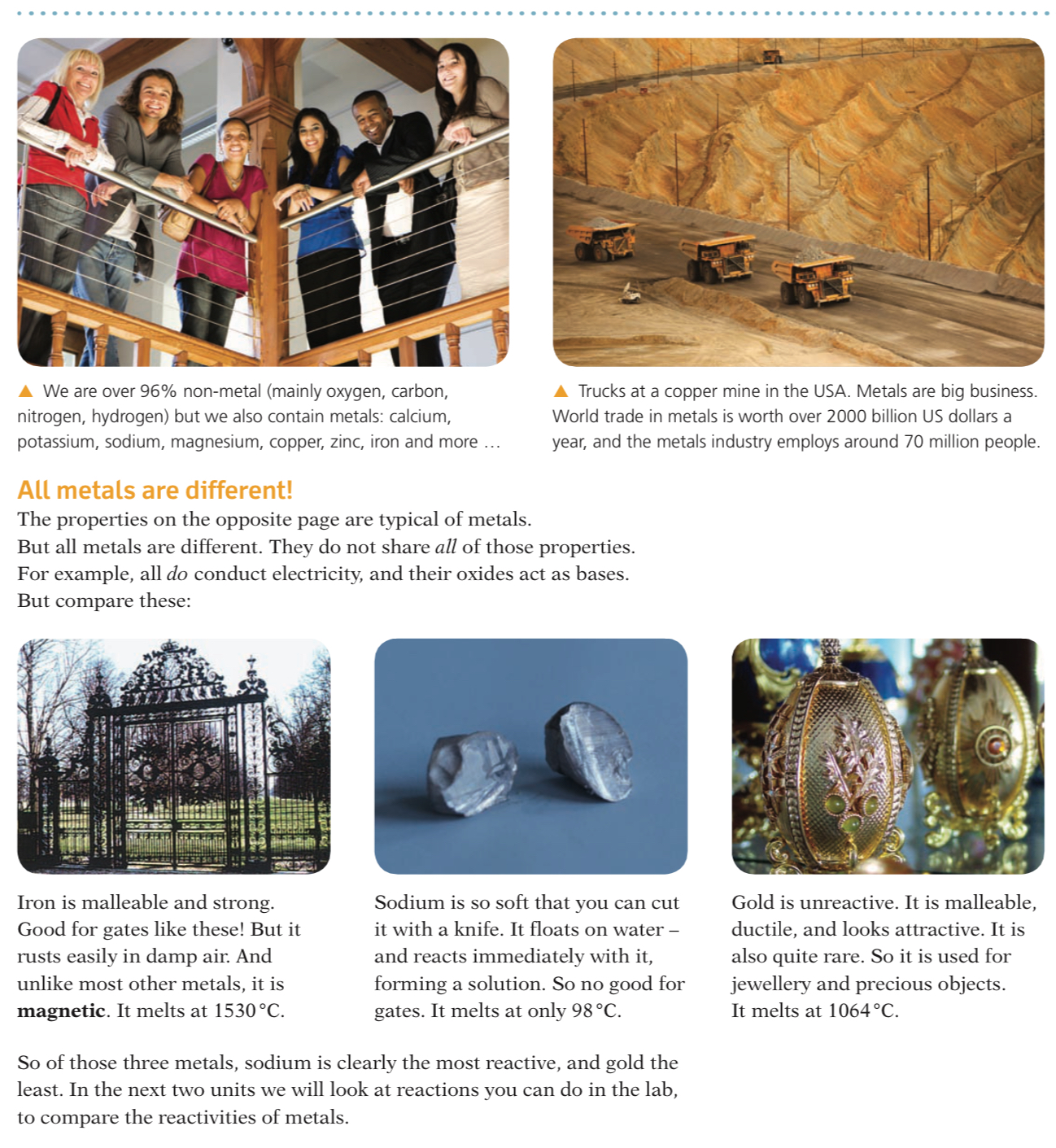

The Earth’s crust contains metals and metal compounds such as gold, copper, iron oxide and aluminium oxide

Useful metals are often chemically combined with other substances forming ores

A metal ore is a rock that contains enough of the metal to make it worthwhile extracting

They have to be extracted from their ores through processes such as electrolysis, using a blast furnace or by reacting with more reactive material

In many cases the ore is an oxide of the metal, therefore the extraction of these metals is a reduction process since oxygen is being removed

Common examples of oxide ores are iron and aluminium ores which are called haematite and bauxite respectively

Unreactive metals do not have to be extracted chemically as they are often found as the uncombined element

This occurs as they do not easily react with other substances due to their chemical stability

They are known as native metals and examples include gold and platinum which can both be mined directly from the Earth’s crust

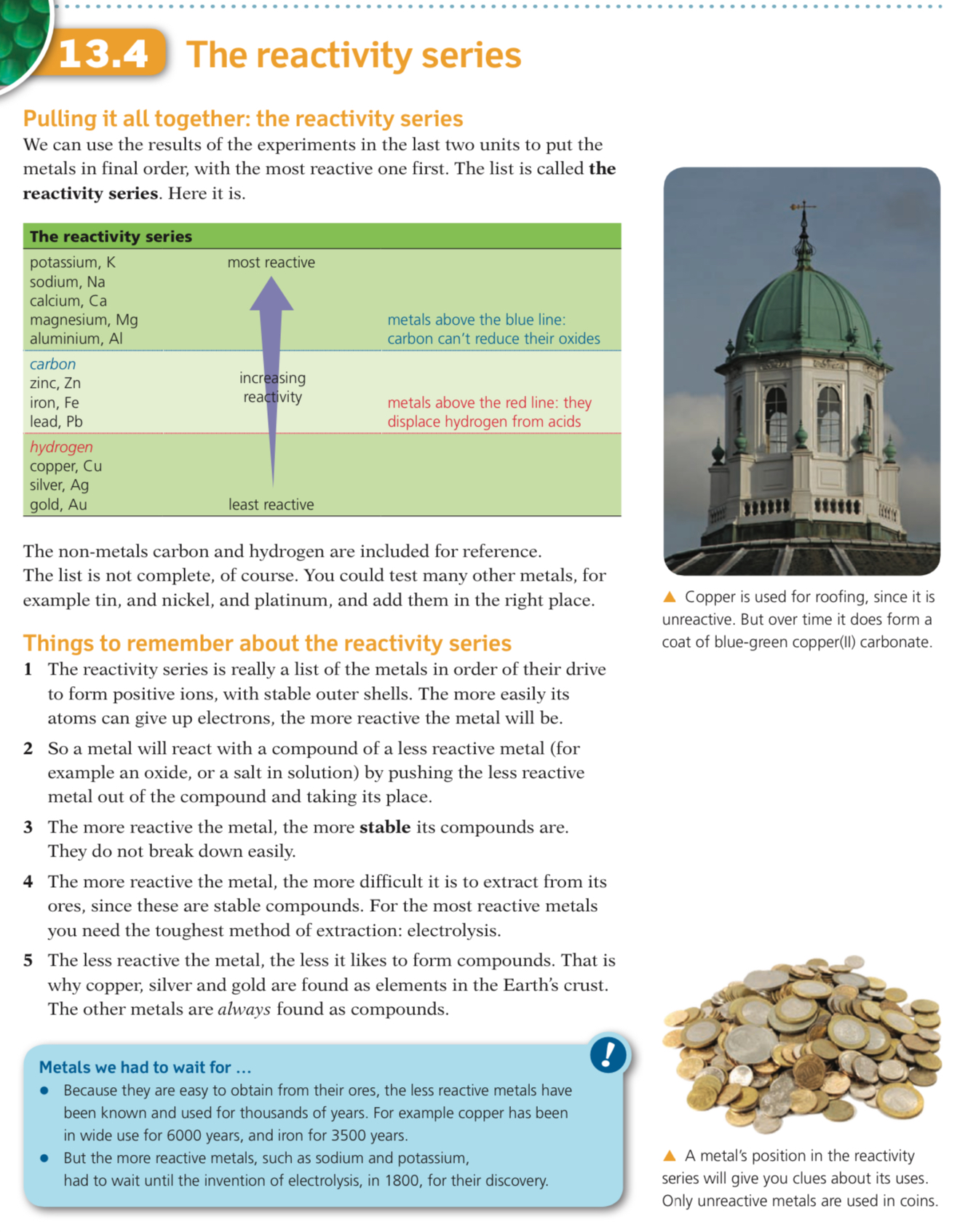

The position of the metal on the reactivity series influences the method of extraction

Those metals placed higher up on the series (above carbon) have to be extracted using electrolysis

Metals lower down on the series can be extracted by heating with carbon

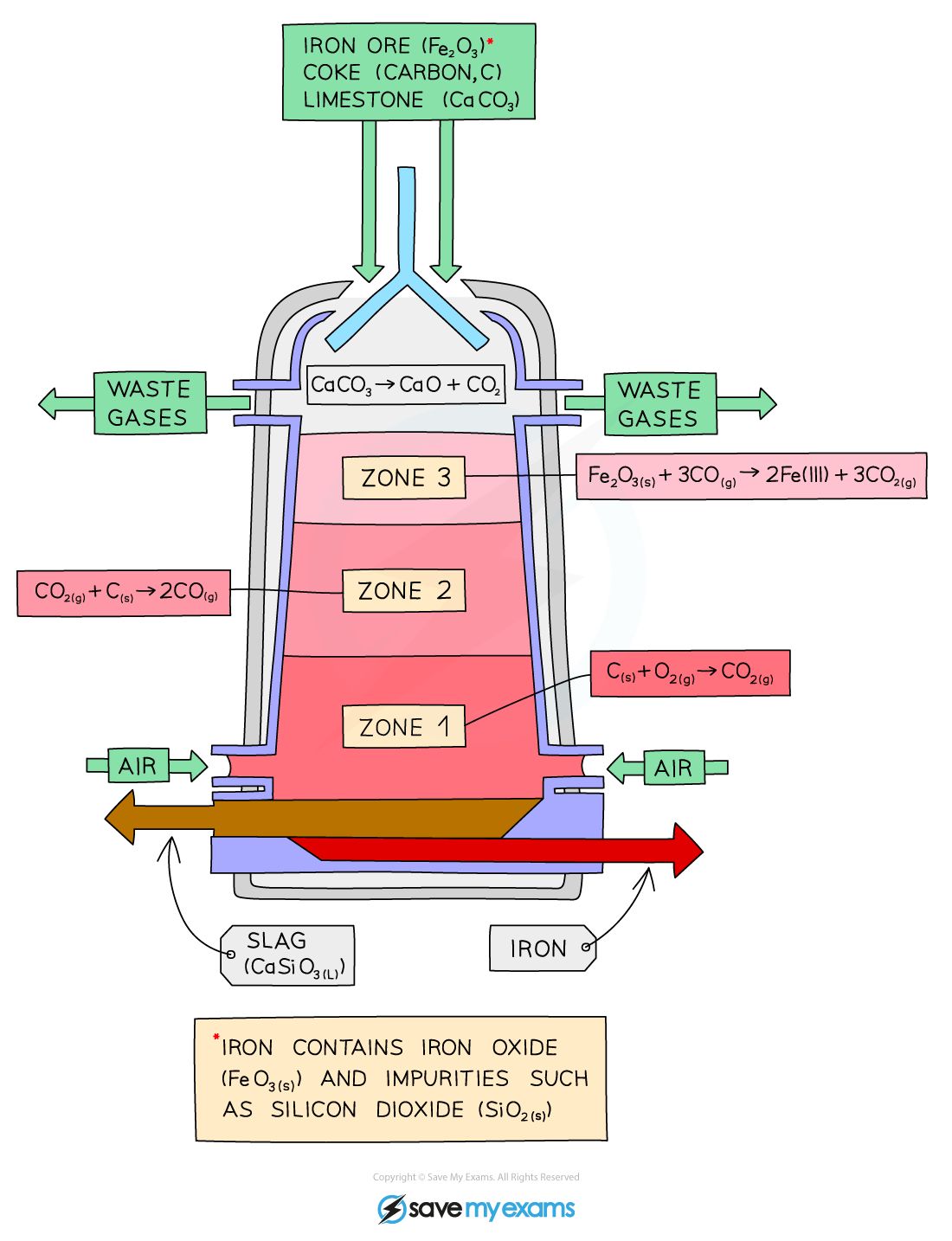

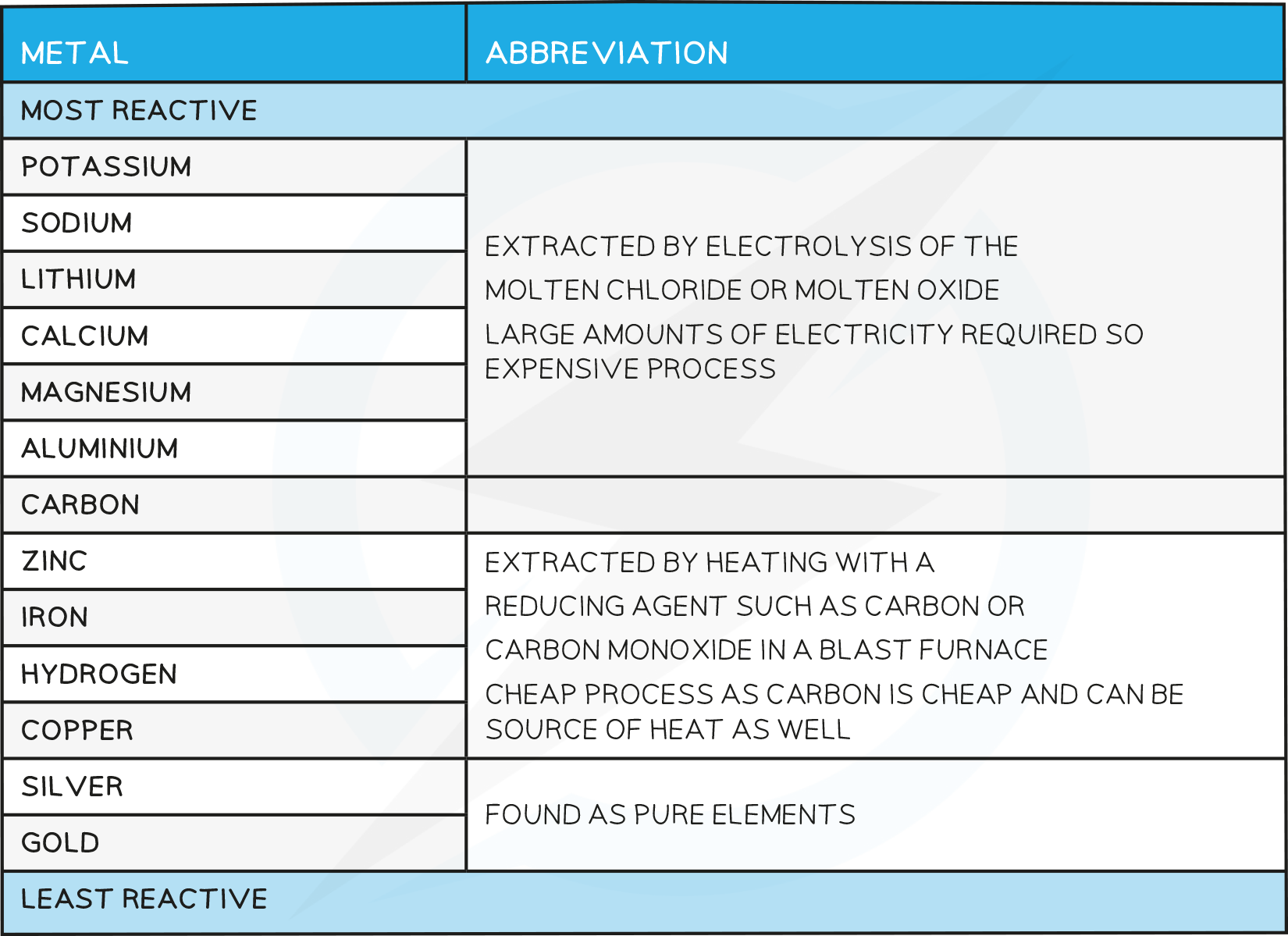

Iron is extracted in a large container called a blast furnace from its ore, haematite

Modern blast furnaces produce approximately 10000 tonnes of iron per day

The process is demonstrated and explained below:

The raw materials: iron ore (haematite), coke (an impure form of carbon), and limestone are added into the top of the blast furnace

Hot air is blown in the bottom

Zone 1:

Coke burns in the hot air forming carbon dioxide

C (s) + O2 (g) → CO2 (g)

Zone 2:

At the high temperatures in the furnace, more coke reacts with carbon dioxide forming carbon monoxide

CO2 (g) + C (s) → 2CO (g)

Zone 3:

Carbon monoxide reduces the iron(III) oxide in the iron ore to form iron

This will melt and collect at the bottom of the furnace, where it is tapped off:

Fe2O3 (s) + 3CO (g) → 2Fe (I) + 3CO2 (g)

Limestone (calcium carbonate) is added to the furnace to remove impurities in the ore.

The calcium carbonate in the limestone decomposes to form calcium oxide:

CaCO3 (s) → CaO (s) + CO2 (g)

CaO (s) + SiO2 (s) → CaSiO3 (l)

The calcium oxide formed reacts with the silicon dioxide, which is an impurity in the iron ore, to form calcium silicate

This melts and collects as a molten slag floating on top of the molten Iron, which is tapped off separately:

CaO (s) + SiO2 (s) → CaSiO3 (l)

The conversion of iron into steel

Molten iron is an alloy of 96% iron, with carbon, phosphorus, silicon and sulfur impurities

It is too brittle for most uses, so most of it is converted into steel by removing some of the impurities

Not all of the carbon is removed as steel contains some carbon, the percentage of which depends on the use of the steel

The molten iron is transferred to an oxygen furnace where the conversion to steel takes place

Oxygen is added which reacts with the carbon forming carbon dioxide and carbon monoxide

These are gases so escape from the furnace

The oxygen also reacts with other impurities, silicon and phosphorus to form acidic oxides

Powdered calcium oxide is then added which is a basic oxide

The acidic silicon and phosphorus oxides react with the powdered calcium oxide and from a slag which is mainly calcium silicate:

SiO2 (l) + CaO (s) → CaSiO3 (s)

The slag floats on the surface of the molten iron and is skimmed off

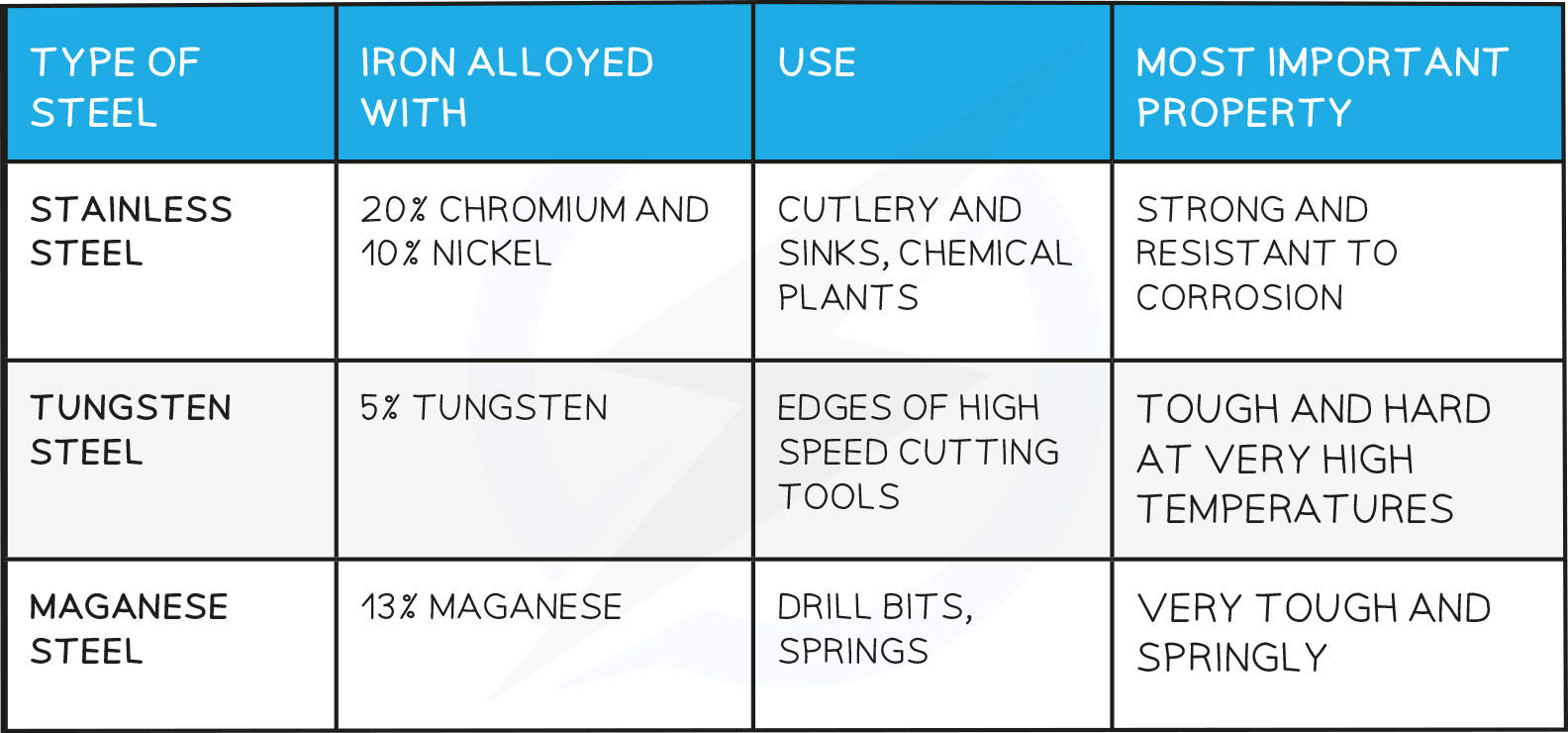

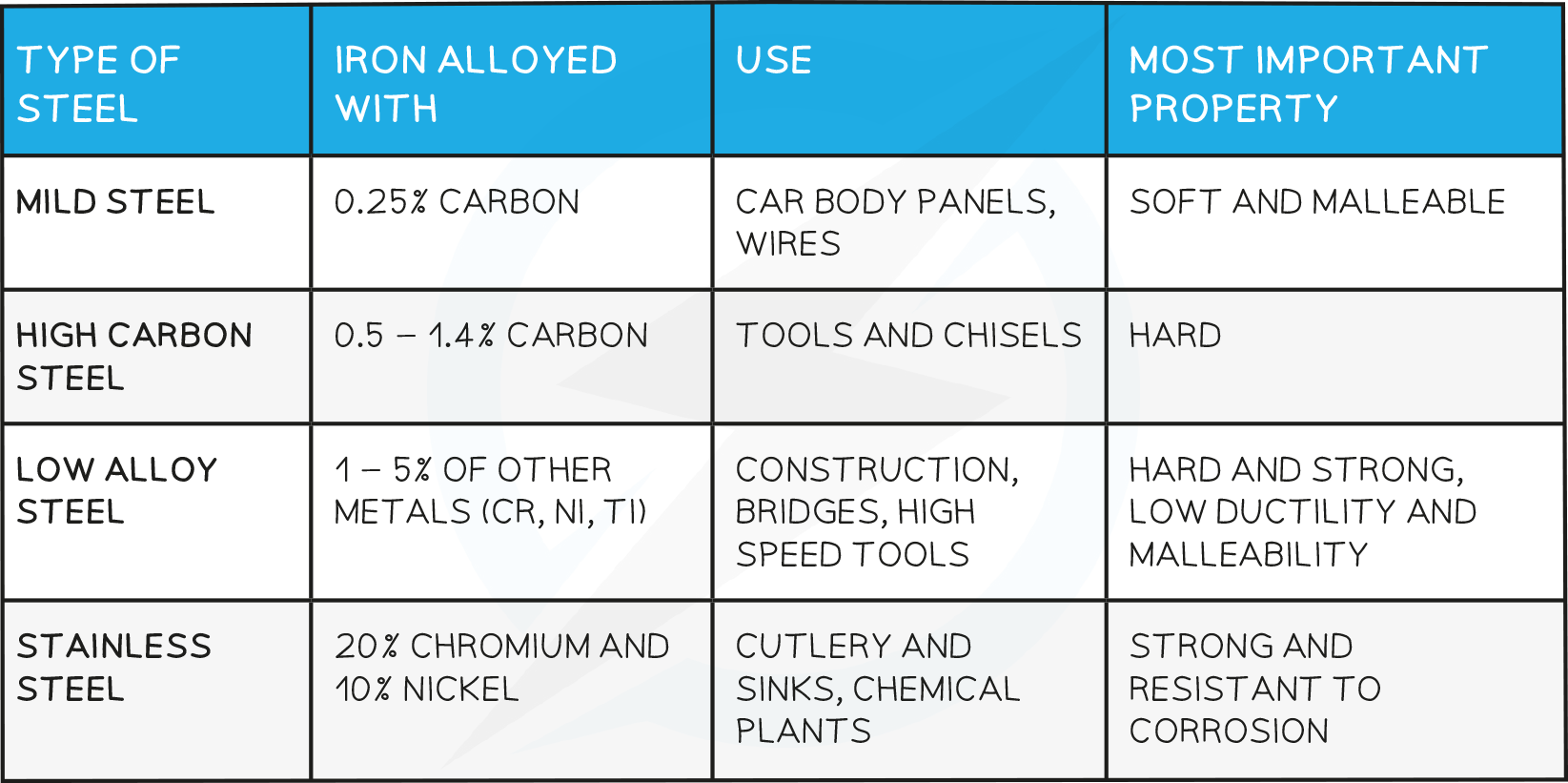

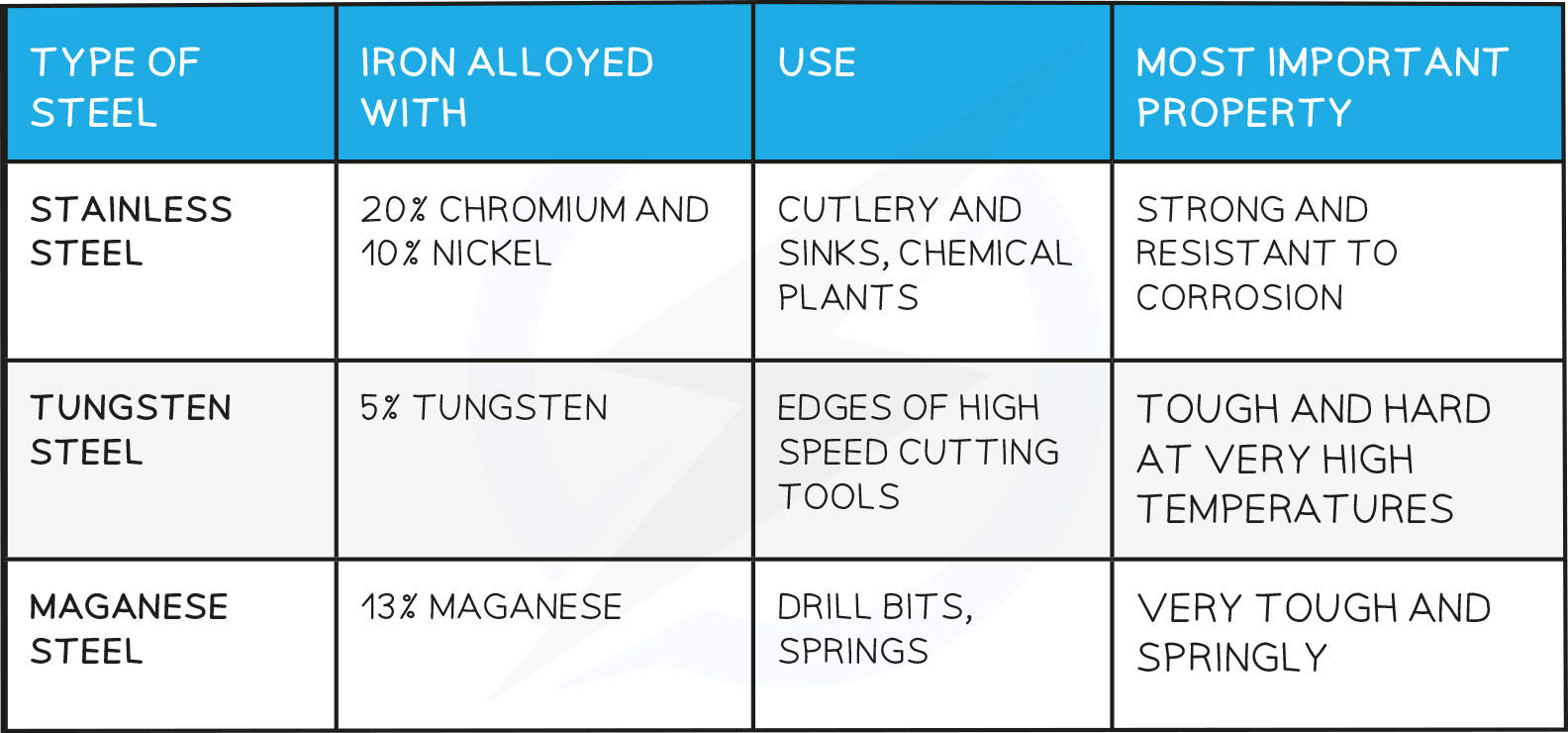

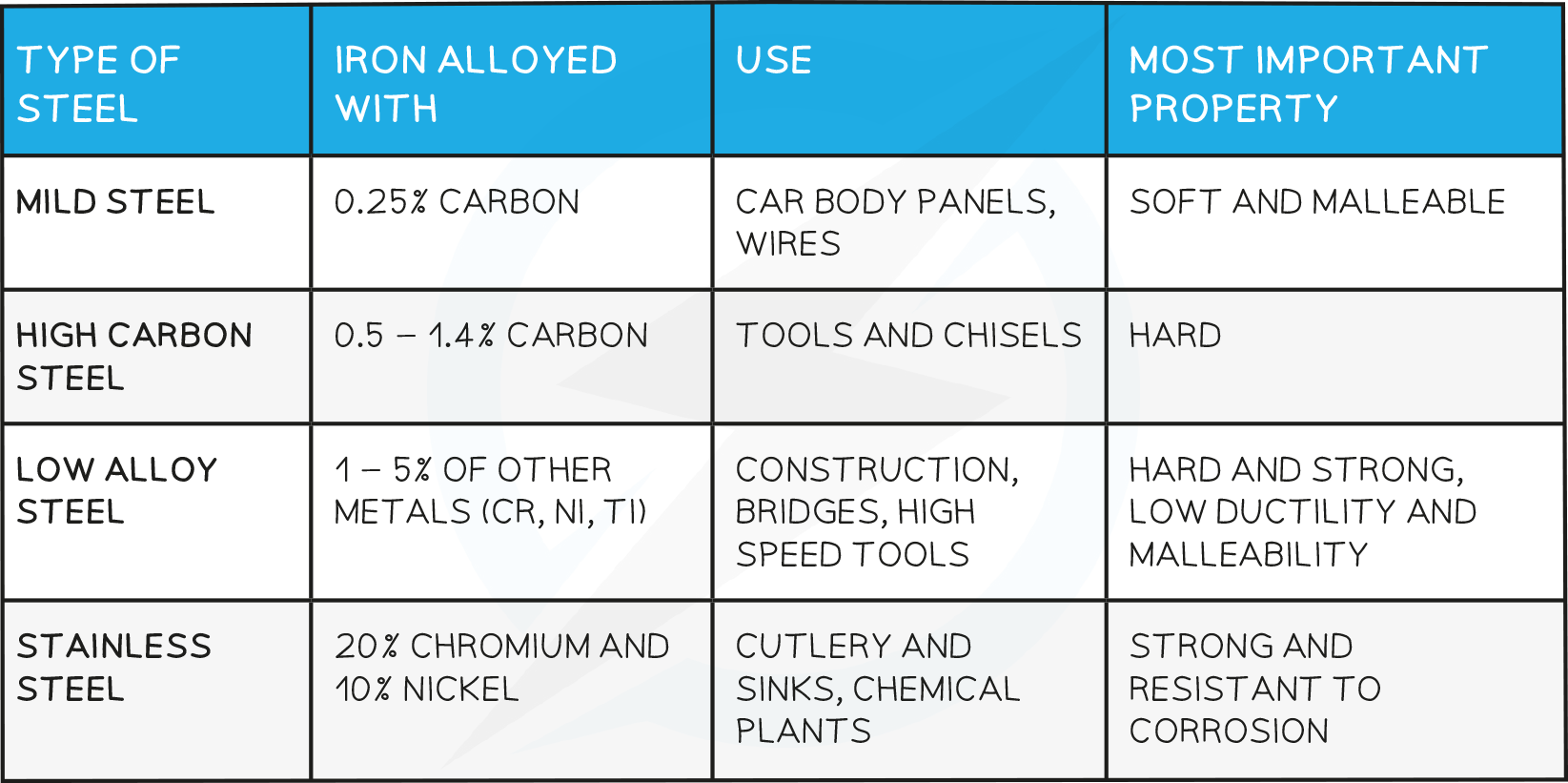

Steel Alloys

The amount of carbon removed depends on the amount of oxygen used

By carefully controlling the amount of carbon removed and subsequent addition of other metals such as chromium, manganese or nickel, the particular type of steel alloy is produced

Aluminum Extractions and Benefit of Recycling

Aluminium is a reactive metal, above carbon in the reactivity series

Its main ore, is bauxite, which is aluminium oxide

Due to aluminium's reactivity, it is extracted by electrolysis

Advantages

Raw materials are conserved (bauxite and haematite)

Reduces the amount of waste sent to landfill

Energy use is reduced, especially in the electrolysis of aluminium

Less air pollution

Disadvantages

Collection and transport of material to be recycled requires energy and fuel

Workers, vehicles and worksites need to be organised and maintained

Materials need to be sorted before they can be recycled which also requires energy and labour

Products made from recycled materials may not always be of the same quality as the original

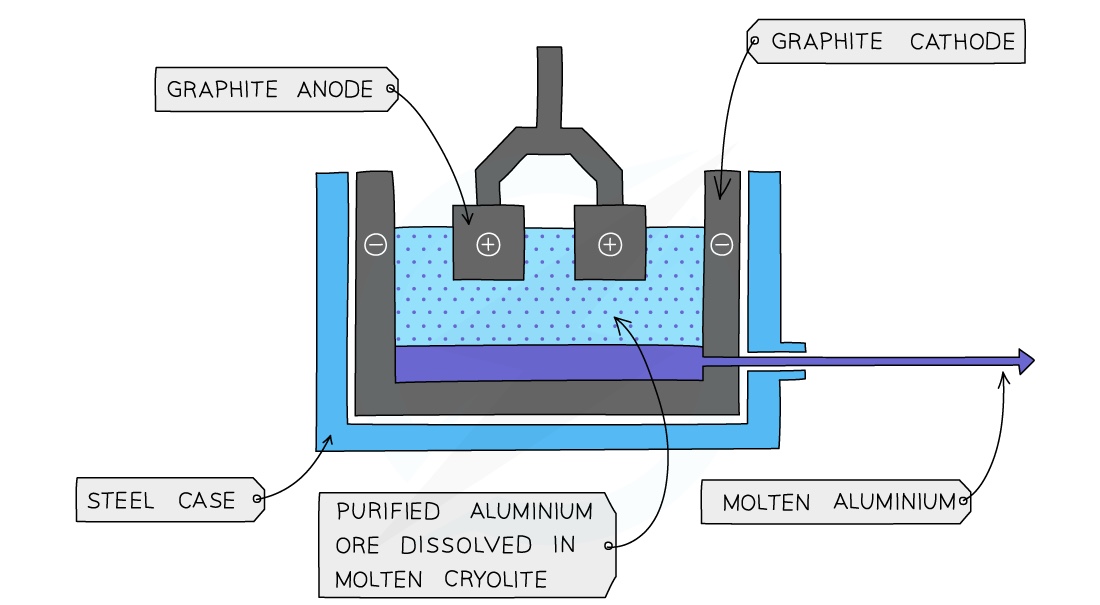

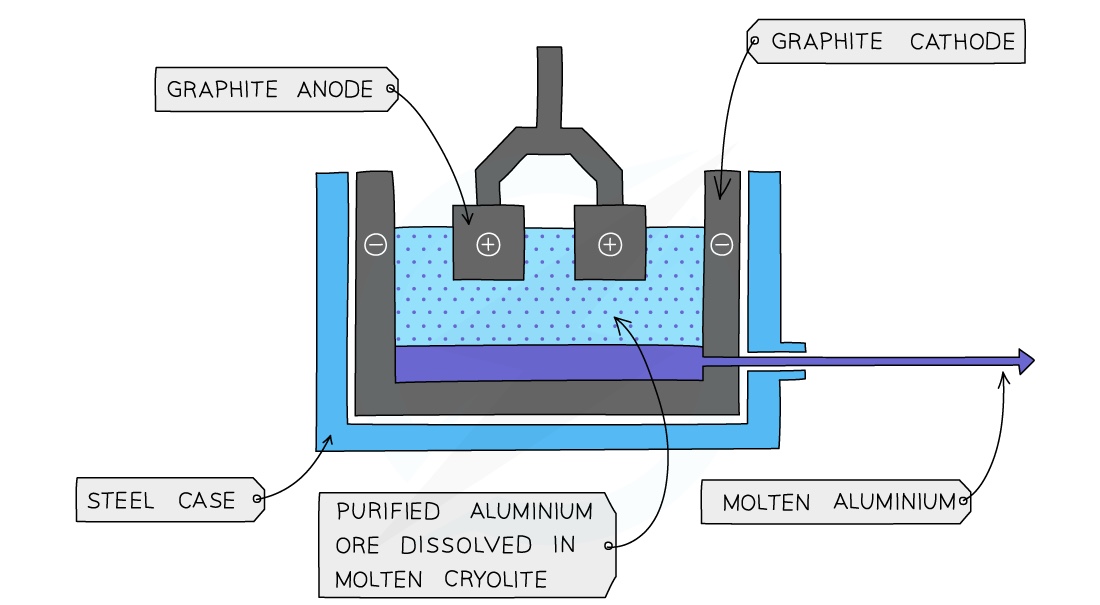

The process of Aluminum Extraction by electrolysis

Bauxite is first purified to produce aluminium oxide Al2O3

Aluminium oxide is then dissolved in molten cryolite.

This is because aluminium oxide has a melting point of over 2000°C which would use a lot of energy and be very expensive. The resulting mixture has a lower melting point without interfering with the reaction

The mixture is placed in an electrolysis cell, made from steel, lined with graphite.

The graphite lining acts as the negative electrode, with several large graphite blocks as the positive electrodes.

At the cathode:

Aluminium ions gain electrons (reduction)

Molten aluminium forms at the bottom of the cell

The molten aluminium is siphoned off from time to time and fresh aluminium oxide is added to the cell.

Al3+ 3e- → Al

At the anode:

Oxide ions lose electrons (oxidation)

Oxygen is produced at the anode:

2O2- → O2 + 4e-

The carbon in the graphite anodes reacts with the oxygen produced to produce CO2

C (s) + O2 (g) → CO2 (g)

As a result the anode wears away and has to be replaced regularly

A lot of electricity is required for this process of extraction, this is a major expense

Zinc Extraction

Zinc is a useful metal, used to galvanize iron, and used to make alloys such as brass

Zinc ore is called zinc blende, which is mainly zinc sulfide, ZnS

The zinc blende is first roasted in air to produce zinc oxide and sulfur dioxide

2ZnS (s) + O2 (g) → 2ZnO (s) + SO2 (g)

The zinc oxide is then reduced in one of two ways

Using carbon monoxide

Electrolysis

Reduction using carbon monoxide:

Carbon burns in a blast of very hot air to form carbon dioxide:

C (s) + O2 (g) → CO2 (g)

The carbon dioxide produced reacts with more coke to form carbon monoxide:

CO2 (g) + C (s) → 2CO (g)

The carbon monoxide is the reducing agent and reduces the zinc oxide to zinc:

ZnO (s) + CO (g) → Zn (s) + CO2 (g)

The mixture produced contains zinc and other impurities

It is separated by fractional distillation

Electrolysis

Zinc oxide needs to be molten but has a high melting point

Is dissolved in sulfuric acid and due to being a base, neutralises it to produce zinc sulfate

At the cathode: zinc ions gains electrons (reduction) to produce zinc

Zn2+ + 2e- → Z

Uses of zinc

Zinc is used in galvanising, the process of coating a metal such as iron or steel with a protective coating of zinc to prevent corrosion or rusting

Galvanising is an effective way of rust protection as it works even if the zinc coating becomes scratched or damaged

ZnCO3 is formed when zinc reacts with oxygen and carbon dioxide in the air and protects the iron by the barrier method

If the coating is damaged or scratched, the iron is still protected from rusting because zinc preferentially corrodes as it is higher up the reactivity series than iron

Compared to iron it loses its electrons more readily:

Zn → Zn2+ + 2e-

The iron stays protected as it accepts the electrons released by zinc, remaining in the reduced state and thus it does not undergo oxidation

The electrons donated by the zinc react with hydrogen ions in the water producing hydrogen gas

2H+ + 2e– → H2

Zinc therefore reacts with oxygen and water and corrodes instead of the iron

Zinc is also used to make an alloy called brass

Brass contains 70% copper and 30% zinc

The addition of zinc makes the alloy much harder and more corrosion resistant than copper alone

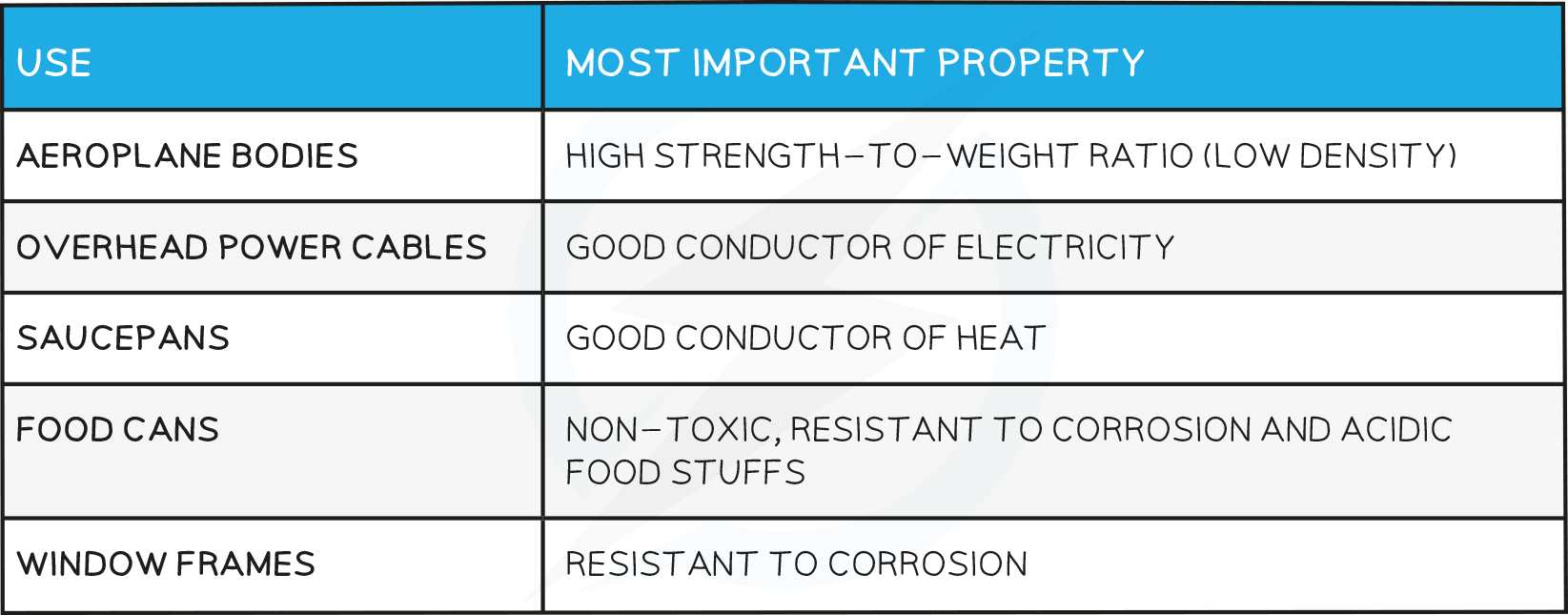

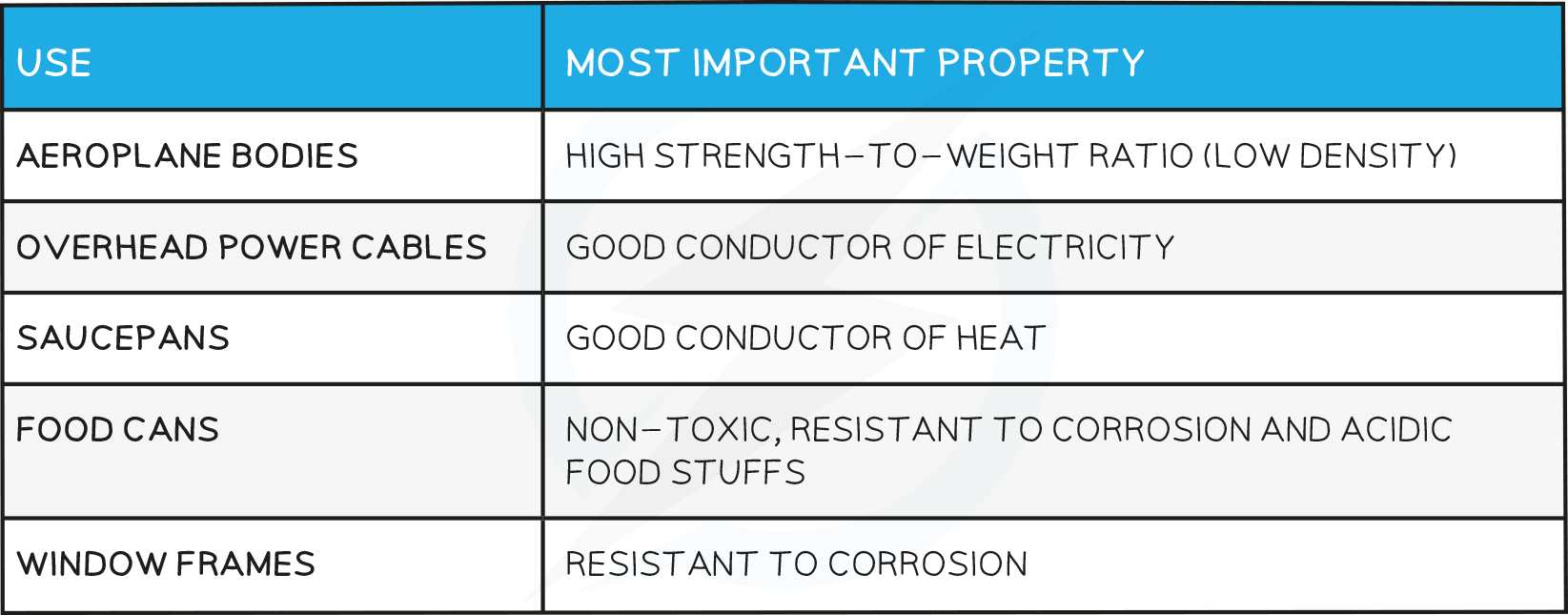

12.4 Uses of Aluminum, Copper and mild steel

Uses of Aluminium

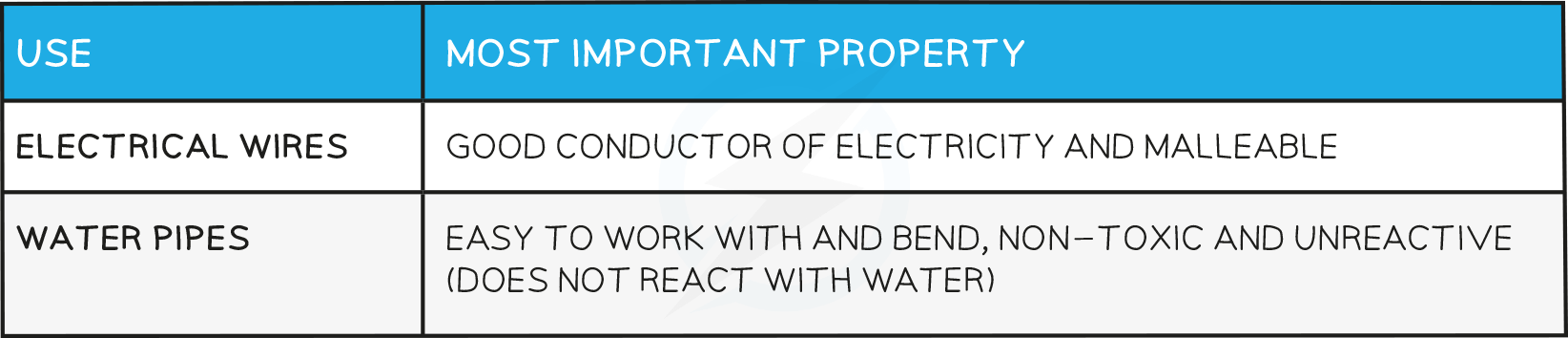

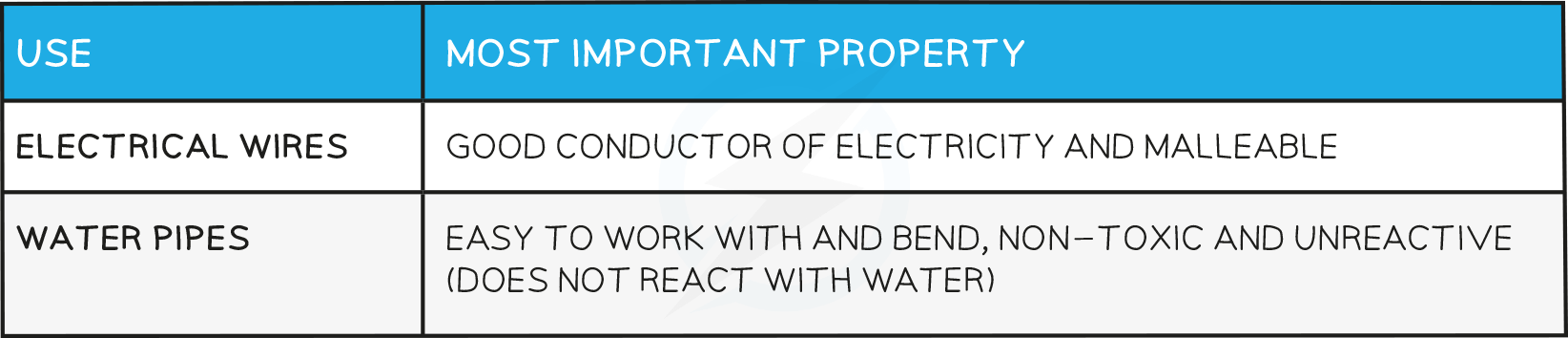

Uses of Copper

Uses of steel:

Pure iron is not useful by itself as it is too soft and rusts very easily

Adding different quantities of carbon and other metals allows the properties to be changed and therefore used in various contexts

It is important to monitor the amount of carbon that has been added to iron- too little and the iron is not strong enough but too much and the iron becomes brittle

Metals 12.1 to 12.4

12.1 Properties of metals

General Chemical Properties

The chemistry of metals is studied by analysing their reactions with water, dilute acid and oxygen

Based on these reactions, a reactivity series of metals can be produced

Reactivity with water

Some metals react with water, either warm or cold, or with steam

Metals that react with cold water form a metal hydroxide and hydrogen gas

metal + water → metal hydroxide + hydrogen

For example calcium:

Ca (s) + 2H2O (l) → Ca(OH)2 (aq) + H2 (g)

Metals that react with steam form metal oxide and hydrogen gas, for example zinc:

Zn (s) + H2O (l) → ZnO (s) + H2 (g)

Reactivity with acids

Most metals react with dilute acids such as HCl

When acids and metals react, the hydrogen atom in the acid is replaced by the metal atom to produce a salt and hydrogen gas, for example iron:

metal + acid → salt + hydrogen

Fe (s) + 2HCl (aq) → FeCl2 (aq) + H2 (g)

Reactivity with oxygen

Unreactive metals such as gold and copper do not react with acids

Some reactive metals such as the alkali metals react easily with oxygen

Copper and iron can also react with oxygen although much more slowly

When metals react with oxygen a metal oxide is formed, for example copper:

metal + oxygen → metal oxide

2Cu (s) + O2 (g) → 2CuO (s)

Typical physical properties of metals :

high melting points.

good conductors of electricity.

good conductors of heat.

high density.

malleable.

ductile.

Chemical Properties of Metals

The density of metals is usually high.

Metals are malleable and ductile.

Metals form an alloy with other metals or non – metals.

Some metals react with air and corrode. ...

Metals are good conductors of heat and electricity. ...

Generally, metals are in a solid state at room temperature

12.2 The Reactivity Series

Based on how metals react with water, dilute acid and oxygen, a reactivity series of metals can be produced

Reactivity of a metal is determined by its tendency to lose electrons and form positive ions

If a metal loses electrons easily it is more reactive than a metal that loses them less easily

The non-metal carbon is also included in the reactivity series as it is used to extract metals from their oxides

it’s important to learn The Reactivity series here’s a nemonic to help

Observations from the table above allow the following reactivity series to be deduced

The order of this reactivity series can be memorised using the following mnemonic

“Please send lions, cats, monkeys and cute zebras into hot countries signed Gordon

12.3 Extraction of Metals

Obtaining metals from there ores

The Earth’s crust contains metals and metal compounds such as gold, copper, iron oxide and aluminium oxide

Useful metals are often chemically combined with other substances forming ores

A metal ore is a rock that contains enough of the metal to make it worthwhile extracting

They have to be extracted from their ores through processes such as electrolysis, using a blast furnace or by reacting with more reactive material

In many cases the ore is an oxide of the metal, therefore the extraction of these metals is a reduction process since oxygen is being removed

Common examples of oxide ores are iron and aluminium ores which are called haematite and bauxite respectively

Unreactive metals do not have to be extracted chemically as they are often found as the uncombined element

This occurs as they do not easily react with other substances due to their chemical stability

They are known as native metals and examples include gold and platinum which can both be mined directly from the Earth’s crust

The position of the metal on the reactivity series influences the method of extraction

Those metals placed higher up on the series (above carbon) have to be extracted using electrolysis

Metals lower down on the series can be extracted by heating with carbon

Iron is extracted in a large container called a blast furnace from its ore, haematite

Modern blast furnaces produce approximately 10000 tonnes of iron per day

The process is demonstrated and explained below:

The raw materials: iron ore (haematite), coke (an impure form of carbon), and limestone are added into the top of the blast furnace

Hot air is blown in the bottom

Zone 1:

Coke burns in the hot air forming carbon dioxide

C (s) + O2 (g) → CO2 (g)

Zone 2:

At the high temperatures in the furnace, more coke reacts with carbon dioxide forming carbon monoxide

CO2 (g) + C (s) → 2CO (g)

Zone 3:

Carbon monoxide reduces the iron(III) oxide in the iron ore to form iron

This will melt and collect at the bottom of the furnace, where it is tapped off:

Fe2O3 (s) + 3CO (g) → 2Fe (I) + 3CO2 (g)

Limestone (calcium carbonate) is added to the furnace to remove impurities in the ore.

The calcium carbonate in the limestone decomposes to form calcium oxide:

CaCO3 (s) → CaO (s) + CO2 (g)

CaO (s) + SiO2 (s) → CaSiO3 (l)

The calcium oxide formed reacts with the silicon dioxide, which is an impurity in the iron ore, to form calcium silicate

This melts and collects as a molten slag floating on top of the molten Iron, which is tapped off separately:

CaO (s) + SiO2 (s) → CaSiO3 (l)

The conversion of iron into steel

Molten iron is an alloy of 96% iron, with carbon, phosphorus, silicon and sulfur impurities

It is too brittle for most uses, so most of it is converted into steel by removing some of the impurities

Not all of the carbon is removed as steel contains some carbon, the percentage of which depends on the use of the steel

The molten iron is transferred to an oxygen furnace where the conversion to steel takes place

Oxygen is added which reacts with the carbon forming carbon dioxide and carbon monoxide

These are gases so escape from the furnace

The oxygen also reacts with other impurities, silicon and phosphorus to form acidic oxides

Powdered calcium oxide is then added which is a basic oxide

The acidic silicon and phosphorus oxides react with the powdered calcium oxide and from a slag which is mainly calcium silicate:

SiO2 (l) + CaO (s) → CaSiO3 (s)

The slag floats on the surface of the molten iron and is skimmed off

Steel Alloys

The amount of carbon removed depends on the amount of oxygen used

By carefully controlling the amount of carbon removed and subsequent addition of other metals such as chromium, manganese or nickel, the particular type of steel alloy is produced

Aluminum Extractions and Benefit of Recycling

Aluminium is a reactive metal, above carbon in the reactivity series

Its main ore, is bauxite, which is aluminium oxide

Due to aluminium's reactivity, it is extracted by electrolysis

Advantages

Raw materials are conserved (bauxite and haematite)

Reduces the amount of waste sent to landfill

Energy use is reduced, especially in the electrolysis of aluminium

Less air pollution

Disadvantages

Collection and transport of material to be recycled requires energy and fuel

Workers, vehicles and worksites need to be organised and maintained

Materials need to be sorted before they can be recycled which also requires energy and labour

Products made from recycled materials may not always be of the same quality as the original

The process of Aluminum Extraction by electrolysis

Bauxite is first purified to produce aluminium oxide Al2O3

Aluminium oxide is then dissolved in molten cryolite.

This is because aluminium oxide has a melting point of over 2000°C which would use a lot of energy and be very expensive. The resulting mixture has a lower melting point without interfering with the reaction

The mixture is placed in an electrolysis cell, made from steel, lined with graphite.

The graphite lining acts as the negative electrode, with several large graphite blocks as the positive electrodes.

At the cathode:

Aluminium ions gain electrons (reduction)

Molten aluminium forms at the bottom of the cell

The molten aluminium is siphoned off from time to time and fresh aluminium oxide is added to the cell.

Al3+ 3e- → Al

At the anode:

Oxide ions lose electrons (oxidation)

Oxygen is produced at the anode:

2O2- → O2 + 4e-

The carbon in the graphite anodes reacts with the oxygen produced to produce CO2

C (s) + O2 (g) → CO2 (g)

As a result the anode wears away and has to be replaced regularly

A lot of electricity is required for this process of extraction, this is a major expense

Zinc Extraction

Zinc is a useful metal, used to galvanize iron, and used to make alloys such as brass

Zinc ore is called zinc blende, which is mainly zinc sulfide, ZnS

The zinc blende is first roasted in air to produce zinc oxide and sulfur dioxide

2ZnS (s) + O2 (g) → 2ZnO (s) + SO2 (g)

The zinc oxide is then reduced in one of two ways

Using carbon monoxide

Electrolysis

Reduction using carbon monoxide:

Carbon burns in a blast of very hot air to form carbon dioxide:

C (s) + O2 (g) → CO2 (g)

The carbon dioxide produced reacts with more coke to form carbon monoxide:

CO2 (g) + C (s) → 2CO (g)

The carbon monoxide is the reducing agent and reduces the zinc oxide to zinc:

ZnO (s) + CO (g) → Zn (s) + CO2 (g)

The mixture produced contains zinc and other impurities

It is separated by fractional distillation

Electrolysis

Zinc oxide needs to be molten but has a high melting point

Is dissolved in sulfuric acid and due to being a base, neutralises it to produce zinc sulfate

At the cathode: zinc ions gains electrons (reduction) to produce zinc

Zn2+ + 2e- → Z

Uses of zinc

Zinc is used in galvanising, the process of coating a metal such as iron or steel with a protective coating of zinc to prevent corrosion or rusting

Galvanising is an effective way of rust protection as it works even if the zinc coating becomes scratched or damaged

ZnCO3 is formed when zinc reacts with oxygen and carbon dioxide in the air and protects the iron by the barrier method

If the coating is damaged or scratched, the iron is still protected from rusting because zinc preferentially corrodes as it is higher up the reactivity series than iron

Compared to iron it loses its electrons more readily:

Zn → Zn2+ + 2e-

The iron stays protected as it accepts the electrons released by zinc, remaining in the reduced state and thus it does not undergo oxidation

The electrons donated by the zinc react with hydrogen ions in the water producing hydrogen gas

2H+ + 2e– → H2

Zinc therefore reacts with oxygen and water and corrodes instead of the iron

Zinc is also used to make an alloy called brass

Brass contains 70% copper and 30% zinc

The addition of zinc makes the alloy much harder and more corrosion resistant than copper alone

12.4 Uses of Aluminum, Copper and mild steel

Uses of Aluminium

Uses of Copper

Uses of steel:

Pure iron is not useful by itself as it is too soft and rusts very easily

Adding different quantities of carbon and other metals allows the properties to be changed and therefore used in various contexts

It is important to monitor the amount of carbon that has been added to iron- too little and the iron is not strong enough but too much and the iron becomes brittle

Knowt

Knowt