Fernando Frías

7 hits in logistics:

the right product

in the right amount

in the right place

at the right time

under the right conditions

at the right cost

to the right customer

Supply Chain

supply chain: global network used to deliver products and services from raw materials to end customers through the flow of information, physical distribution and cash. supply chain flows: product, money, information, energy.

A supply chain is like a big team that works together to get products and services from the very beginning to the people who want to buy them. It's like a long journey that involves different steps and lots of different things moving around.

Imagine you want to buy a toy. Before you can play with it, the toy needs to be made. The supply chain starts with getting the raw materials, like plastic and metal, to make the toy. These materials are then sent to a factory where the toy is put together.

Once the toy is made, it needs to be sent to the store where you can buy it. This is called the physical distribution part of the supply chain. The toy might travel on a truck, a ship, or even an airplane to reach the store.

But that's not all! Along the way, there are other important things that need to flow through the supply chain. One of them is information. This means that everyone involved in making and delivering the toy needs to know what's happening. They need to know how many toys are being made, where they are going, and when they will arrive at the store.

Another important thing that flows through the supply chain is money. The people who make the toy and transport it need to get paid, right? So, money needs to move from the store to the factory and all the other places involved.

Lastly, energy is also part of the supply chain. Think about the fuel needed to power the trucks, ships, and airplanes that transport the toy. Without energy, the toy wouldn't be able to make its way to the store.

So, in summary, a supply chain is like a big team that works together to get products and services to you. It involves the flow of products, money, information, and energy. Each step is important to make sure everything gets to where it needs to go.

Value Chain

value chain: it comprises the functions within a company that add value to the goods or services that the organization sells to customers and for which it receives payment.

Imagine you have a lemonade stand. You start with lemons, sugar, and water, and you turn them into delicious lemonade. Then, you sell the lemonade to your customers and they give you money in return.

Now, think of a big company like a toy factory. They have many different steps, or functions, to make and sell their toys. The value chain is like a series of steps that add value to the toys and help the company make money.

First, the toy factory needs to design the toys. They come up with cool ideas and draw pictures of what the toys will look like. This is the first step in the value chain.

Next, they need to buy the materials to make the toys. They get things like plastic, paint, and batteries. These materials are used to actually create the toys. This is the second step.

After that, the factory workers start making the toys. They use machines and tools to shape the plastic, paint the toys, and put in the batteries. This is the third step.

Once the toys are made, they need to be packaged. The factory workers put the toys in boxes and add labels and instructions. This is the fourth step.

Now, the toys are ready to be sent to stores. The factory ships the toys to different stores around the world. This is the fifth step.

Finally, the stores sell the toys to customers. People come to the stores, see the toys, and decide to buy them. The stores make money from selling the toys. This is the last step in the value chain.

So, the value chain is all the steps a company goes through to add value to their products and make money. Each step is important because it helps create a product that customers want to buy.

logistics

moving one product from point a to point b, moving from point b to point c. It is the functional point that provides for the physical movement of items between raw materials, factories, warehouses and customers.

the base of everything is the customer because it has a need, wants to pay (cost), knowledge (you gotta know how to pay, como entrar para atacar la necesidad), and convenience. 4p´s.

take control of the inventory or you´ll lose money.

Logistics is like a big game of moving things from one place to another. Imagine you have a toy car that you want to send to your friend who lives far away. First, you need to get the toy car from your house (point A) to the post office (point B). Then, the post office needs to send it to your friend's house (point C).

Logistics is all about making sure this process happens smoothly. It involves moving things like raw materials (the stuff that makes the toy car), the toy car itself, and even other products that people want to buy.

The most important part of logistics is the customer. The customer is the person who wants to buy or receive the product. They have a need or want for the product, they are willing to pay for it, they know how to pay for it, and they want it to be convenient. These are called the 4 P's: need, payment, knowledge, and convenience.

So, logistics is like a big puzzle where we figure out how to move things from one place to another, making sure the customer gets what they need in a way that is easy for them.

compra post distribuida

la compra ya viene surtida por tienda.

La compra post distribuida es cuando compras algo y la tienda ya tiene todo listo para ti. Imagina que quieres comprar comida en el supermercado, pero en lugar de tener que ir a buscar cada producto en los estantes, la tienda ya ha recogido todos los productos que necesitas y los ha puesto juntos en un solo lugar. Así, cuando llegas a la tienda, solo tienes que recoger tu compra y pagar en la caja. Es como si alguien hubiera hecho la compra por ti y solo tienes que recogerla. Esto puede ser muy conveniente porque ahorra tiempo y esfuerzo.

principles of inventory and warehousing

variations: delays or incomplete delivery, demand changes, seasonality, spot orders.

restrictions: purchase minimums, lead time(time the supplier takes to deliver the product), quotas (like a condition), review periods (you make your order today but the orders are only on mondays), warehouse capacity, cash flow, product useful life.

Inventory and warehousing are important concepts in managing products and making sure they are available when people want to buy them. Let's break it down!

Inventory is like a big collection of things that a company has to sell. It can be things like toys, clothes, or even food. When a company has a lot of inventory, it means they have a lot of things to sell. But having too much inventory can be a problem because it costs money to store and manage all those things.

Warehousing is like a big storage place where companies keep their inventory. It's like a giant closet or a big warehouse building. Warehouses have shelves and racks to organize the inventory and make it easy to find things when they are needed.

Now, let's talk about some important principles of inventory and warehousing:

Delays or Incomplete Delivery: Sometimes, the things that a company orders may not arrive on time or may not be complete. This can cause problems because the company may not have enough inventory to sell to customers.

Demand Changes: The amount of things that people want to buy can change over time. For example, during the holiday season, people may want to buy more toys. Companies need to be prepared for these changes in demand and have enough inventory to meet the needs of their customers.

Seasonality: Some products are more popular during certain times of the year. For example, swimsuits are more popular in the summer. Companies need to plan their inventory and warehousing based on these seasonal changes in demand.

Spot Orders: Sometimes, companies may need to order more inventory quickly to meet unexpected demand. These are called spot orders. Warehousing needs to have enough space to store these extra items until they are sold.

There are also some restrictions that companies need to consider when managing their inventory and warehousing:

Purchase Minimums: Some suppliers may have a minimum quantity that a company needs to order. This means that the company cannot order just a few items, they have to order a certain amount.

Lead Time: Lead time is the time it takes for the supplier to deliver the ordered products. Companies need to plan their inventory and warehousing based on this lead time to make sure they have enough inventory when they need it.

Quotas: Quotas are like conditions that suppliers may have. For example, a supplier may only allow a company to order a certain

warehouse process

reception - putaway - packaging - shipping - control.

Sure! Imagine you have a big warehouse where you store lots of things like toys, clothes, and books. There are different steps that happen in the warehouse to make sure everything is organized and ready to be sent to people who want to buy them. Let's break down the process into five simple steps:

Reception: This is where all the new things arrive at the warehouse. Just like when you receive a package at home, the warehouse workers receive the items and check if everything is there and in good condition. They make a list of what they received.

Putaway: After the items are checked, they need to be put in the right place in the warehouse. It's like when you clean your room and put your toys back in their proper places. Warehouse workers find a spot for each item so they can easily find it later when someone wants to buy it. (a veces se depends del operator pq la pone en donde sea)

quality assurance: that it is okay

damage: if there is damage you send it to other options or you return it (take a photo, a document, send emails)

Packaging: When someone buys something from the warehouse, the workers need to pack it up nicely and safely. They put the item in a box or a bag and make sure it's protected so it doesn't get damaged during shipping. It's like when you wrap a gift for your friend's birthday.

concentration

pack and hold: you are going to send it later

top off replenishment

yard staying

Shipping: This is when the packed items are ready to leave the warehouse and go to their new owners. The warehouse workers put the packages on trucks or planes to send them to different places. It's like when you give a letter to the mailman to send it to your grandma who lives far away.

Control: This step is important to make sure everything is going smoothly. The warehouse workers keep track of what items are coming in and going out. They check if any mistakes were made and fix them. It's like when you double-check your homework to make sure you didn't make any errors.

So, the warehouse process goes like this: First, the items are received and checked. Then, they are put in the right place in the warehouse. After that, the items are packed nicely for shipping. Next, they are sent out to their new owners. Finally, the workers keep an eye on everything to make sure it's all going well.

ERP (enterprise resource planning) software

system that controls the company total. accounting(internal), finance(external), hr, procurement (items, suppliers, po´s), sales.

ERP (Enterprise Resource Planning) Software

Imagine you have a big company with lots of different departments like accounting, finance, human resources, procurement, and sales. Each department has its own important tasks and information. But it can be really hard to keep track of everything and make sure everyone is working together smoothly.

That's where ERP software comes in! ERP stands for Enterprise Resource Planning. It's like a super smart computer program that helps manage and control all the different parts of a company. It's like the boss of the company's computer system!

ERP software helps the company keep track of its money, like how much it's spending and how much it's making. It also helps with things like paying employees and keeping track of important financial information.

But ERP software doesn't just help with money stuff. It also helps with other important things like managing employees and their information, like their names, addresses, and job titles. It helps with buying things the company needs, like supplies or equipment, by keeping track of what's in stock and when to order more. It even helps with selling things by keeping track of customers and orders.

So basically, ERP software is like a big computer program that helps a company manage and control all the different parts of its business. It keeps everything organized and makes sure everyone is working together smoothly. It's like having a super smart assistant that helps the company run smoothly and be successful!

WMS: warehouse management system.

A warehouse management system, or WMS for short, is like a super smart computer program that helps people manage and organize things in a big warehouse. Imagine a huge storehouse filled with all kinds of items like toys, clothes, and food. It can be really hard to keep track of where everything is and make sure things are stored properly. That's where a WMS comes in!

Think of a WMS as a boss that tells workers where to put things and keeps track of what's in the warehouse. It uses special technology like barcodes or radio frequency identification (RFID) to keep tabs on all the items. When something new comes into the warehouse, the WMS gives it a special code and tells the workers where to put it. This way, everything has its own special spot and it's easy to find later.

But that's not all! The WMS also helps with other important tasks. It can tell workers when it's time to restock items that are running low, so the store never runs out of things to sell. It can also help plan the best way to move items around the warehouse, so workers don't waste time and energy. Plus, it can keep track of important information like how many items are sold each day, so the store knows what's popular and what's not.

In summary, a warehouse management system is like a super smart computer program that helps people keep track of and organize things in a big warehouse. It tells workers where to put things, keeps track of what's in the warehouse, helps restock items, and makes sure everything runs smoothly.

Warehouse control system

A warehouse control system (WCS) is a software application that manages and controls the operations within a warehouse. It is responsible for directing the flow of work within the warehouse, optimizing processes, and ensuring efficient use of resources. WCS works in conjunction with warehouse management systems (WMS) to coordinate tasks such as picking, packing, and shipping of goods. One key feature of WCS is its ability to communicate with automated material handling equipment, such as conveyor systems, sorters, and robots, to ensure smooth and accurate movement of goods throughout the warehouse. By integrating with various technologies and systems, WCS helps improve warehouse efficiency, accuracy, and productivity. Overall, a well-implemented WCS plays a crucial role in streamlining warehouse operations and enhancing overall supply chain performance.

operation flow of a warehouse (it determines the bases of the logistics and operational capabilities)

suppliers - reception - putaway - picking - shipping - customers

Sure! Imagine a warehouse as a big storehouse where things are stored and organized. The operation flow of a warehouse is like a step-by-step process that helps keep everything running smoothly.

Suppliers: The first step is when suppliers bring in the products to the warehouse. Suppliers are like the people who bring groceries to a store.

Reception: Once the products arrive, the warehouse workers check and count them to make sure everything is correct. It's like when you go to a store and the cashier checks the items you want to buy.

Putaway: After the products are checked, they need to be put away in the right place. Warehouse workers organize the products on shelves or in designated areas. It's like when you put your toys back in their proper places after playing with them.

Picking: When a customer places an order, warehouse workers go to the shelves and pick the items that the customer wants. It's like when you ask your mom to get you a specific toy from your toy box.

Shipping: Once the items are picked, they are packed securely in boxes or packages. Then, they are sent out for delivery to the customers. It's like when you put your toy in a box and give it to the mailman to send it to your friend.

Customers: Finally, the customers receive the products they ordered and are happy! They can use or enjoy the items they received. It's like when you receive a package in the mail and open it to find a new toy to play with.

So, the operation flow of a warehouse goes from suppliers bringing in products, to reception and checking, then organizing and storing the products, picking the items for orders, shipping them out, and finally, the customers receiving and enjoying their purchases.

Sales and Operations Planning

aggregated planning, capacity management and its restrictions in different time horizons,

Types of enterprises:

Retail: Walmart, Soriana

Industry

Services: consultancy

Projects

Public

Sales and Operations Planning (S&OP) is a way for businesses to plan and manage their activities. It helps them make decisions about how much to produce, how much to sell, and how to use their resources effectively.

Imagine you have a lemonade stand. You need to plan how many lemons, sugar, and cups to buy, and how much lemonade to make each day. S&OP is like that, but for bigger businesses.

S&OP involves different types of planning. One is aggregated planning, which means looking at the big picture and making plans for the whole business. For example, Walmart plans how much stuff to buy for all its stores across the country.

Another part of S&OP is capacity management. This means figuring out how much the business can produce or provide. For example, a factory needs to know how many cars it can make in a month.

But there are restrictions too. Sometimes, businesses can't produce as much as they want because of limitations. For example, a factory might not have enough workers or machines to make more cars.

S&OP also looks at different time horizons. This means planning for different periods of time. For example, a retail store like Walmart plans for the whole year, while a factory might plan for just a month.

There are different types of enterprises that use S&OP. Retail businesses like Walmart and Soriana use it to plan how much stuff to buy and sell in their stores. Industries use it to plan how much to produce and manage their resources. Service businesses like consultancies use it to plan their projects and allocate their resources. Public organizations also use it to plan their activities and manage their resources.

In summary, Sales and Operations Planning is a way for businesses to plan and manage their activities. It involves looking at the big picture, managing resources, and making decisions about what to produce and sell. Different types of businesses use it to plan for different time periods and manage their operations effectively.

Product life cycle

The product life cycle is like the journey of a product from when it is first made to when it is no longer used or sold. It has four main stages: introduction, growth, maturity, and decline.

Introduction: This is when a new product is introduced to the market. It's like when a new toy comes out and everyone wants to try it. Companies spend a lot of time and money to make people aware of the product and convince them to buy it.

Growth: Once people start buying the product, it enters the growth stage. It's like when the toy becomes really popular and everyone wants to have it. The company starts making more of the product to meet the demand, and they may even make improvements to make it better.

Maturity: After a while, the product reaches the maturity stage. It's like when the toy is not as exciting anymore because everyone already has it. Sales may start to slow down, but the product is still being sold. Companies may lower the price or offer special deals to keep people interested.

Decline: Eventually, the product enters the decline stage. It's like when the toy is no longer popular and people are not buying it as much. The company may decide to stop making the product or replace it with something new and better.

So, the product life cycle is all about how a product goes through different stages, from being new and exciting to becoming less popular and eventually being replaced.

Demand types:

Dependent demand:

derives from the need to assemble or manufacture a product and is generated according to the structure of a product, they are the component parts, sub assembles and raw materials which are necessary for the finished product and manufacturing

Dependent demand is when we need certain things to make a product. These things can be parts, smaller pieces, or even raw materials. They are all necessary to put together the finished product. So, if we want to make a toy car, we need wheels, a body, and other parts. These parts are dependent on each other because we can't make the toy car without them. It's like building with Lego blocks - we need all the different pieces to make the final creation. The demand for these parts and materials is based on how many finished products we want to make. So, if we want to make 10 toy cars, we need 40 wheels, 10 bodies, and all the other parts that go into making them. Dependent demand helps us plan and organize the manufacturing process so that we have everything we need to make the products efficiently.

Independent Demand:

generated directly from customers need, finished product or a spare part that is requested for sale directly in a customer and is billed in a product sale.

Imagine you have a toy store, and you sell all kinds of toys to kids. Sometimes, kids come to your store and ask for a specific toy they want to buy. This is called independent demand.

Independent demand is when customers directly ask for a particular product or spare part that they want to buy. It could be a finished product, like a toy or a game, or it could be a spare part for something they already have, like a missing puzzle piece or a broken toy part.

When customers ask for these things, you sell them the product they want, and they pay you for it. You then give them a bill, which is like a receipt that shows how much they need to pay for the product.

So, independent demand is all about customers needing and asking for specific things that they want to buy directly from you. It's different from other types of demand, like when you decide to make more toys to sell in your store without anyone asking for them.

Remember, independent demand is when customers generate the need for a product, and you sell it to them directly.

push vs pull process

push: anticipates demand, implies forecasting, proactive process

pull:it is a response to a work order the demand is known and real

Push and Pull in a Simple Way

Push and pull are two different ways of doing things, especially when it comes to getting work done or making products. Let's imagine we are talking about making yummy cupcakes!

Push: Anticipating Demand

Push is like when you make a lot of cupcakes even before anyone asks for them. It's like you are guessing that people will want cupcakes, so you make a bunch in advance. This is called "anticipating demand" or "forecasting." It's a proactive process because you are taking action before knowing for sure if people will actually want the cupcakes.

Pull: Responding to Demand

Pull, on the other hand, is when you make cupcakes only when someone asks for them. It's like you have a special order from someone who really wants cupcakes, so you make them specifically for that person. In this case, the demand is known and real because someone has already asked for the cupcakes.

So, push is about making things before people ask for them, while pull is about making things when people actually want them. Both ways have their own advantages and are used in different situations. It's like having different tools in your toolbox and using the right one for the job!

Remember, push is like guessing what people want and making things in advance, while pull is about making things when someone asks for them.

Order Management

management of various activities associated with the order cycle. This process consists in 4 parts.

order transmittal:

order processing: refers to the time when the seller receives the order until a location (warehouse) is authorized to fill the order

order picking and assembly: all activities from when the warehouse is authorized to fill the order until goods are loaded on board an outbound carrier.

order delivery: is the final phase of order cycle and refers to the time when a transportation carrier picks up the shipment until it is received by the customer.

Supply planning schemes

Past: based on historical behavior based on descriptive statistical data, future will behave like the past, risk of not being aware of what will happen in the future

present

future: based on a forecast of independent or dependent variables, based on quantitative or qualitative forecasting techniques, to anticipate what will happen in the future, risk of erring in the forecast

Supply Planning Schemes

In simple terms, supply planning schemes are ways to figure out how much of something we need in the future.

In the past, people used to look at how things happened before to guess what will happen in the future. They looked at numbers and facts to make predictions. But sometimes, things can change and we might not know what will happen next. This is a risk because we might not be prepared for what's coming.

Nowadays, we have better ways to plan for the future. We use a forecast, which is like a guess, to predict what will happen. We look at different things that can affect the future, like how many people want to buy something or how much money people have. We can use numbers or even people's opinions to make these predictions.

But there's a risk with this too. Sometimes, our guess can be wrong and we might plan for too much or too little of something. This can cause problems because we might not have enough of what people want or we might have too much and waste it.

So, supply planning schemes are ways to help us plan for the future by looking at what happened before or making educated guesses. But we always need to be careful because we can't be 100% sure about what will happen.

Forecast

process that allows estimating what will happen in the future. there are various methods.

4 characteristics: are usually (always) wrong because of the random factor, they must be accompanied by a measure of error, the forecast error measure (standard deviation) quantifies the degree of confidence in the forecast, aggregate forecasts are more accurate than detailed forecasts. summarization reduces variability, in the longer term it is the less certain prognosis. with better info, a better prediction is made.

Forecast

A forecast is like predicting what will happen in the future. It's a way to estimate or guess what might happen based on information we have. There are different ways to make forecasts.

Here are four important things to know about forecasts:

Forecasts are usually not 100% accurate because there are random things that can happen and change the outcome. So, it's like making a guess, but we know it might not be exactly right.

When we make a forecast, we also need to say how confident we are in that guess. We do this by using something called a forecast error measure, which tells us how much we might be off by. It's like saying, "I think it will be sunny tomorrow, but there's a chance it might rain."

When we make forecasts for a big group of things together, like a whole city or country, they tend to be more accurate than when we try to predict specific details for each thing. It's like if we try to guess how many candies each person will eat at a party, it's harder to be right for each person, but easier to guess the total number of candies everyone will eat.

Forecasts become less certain the further into the future we try to predict. It's easier to guess what might happen tomorrow than what might happen in a year. But if we have more information, like weather patterns or trends, we can make better predictions.

So, a forecast is like making an educated guess about what might happen in the future, but we know it might not be exactly right because of random things that can happen. The more information we have and the bigger the group we're predicting for, the better our forecast can be.

What can be predicted are classified in 2 events

repeating events: they occur and will occur naturally and persistently over time. we can analyze their regularity based on their trend and seasonality to be able to anticipate their evolution in the future.

extraordinary events: they occur completely unforeseen and we do not have a good enough chance of estimating their occurrence in the future.

Understanding the inventory logic

Assumptions EOQ (economic order quantity)

The demand is a daily constant (D)

We all time ask the time quantity (Q)

every time we order, we pay cost (Ct)

The cost to keep stock per day is (h) per each SKU

The delivery time from the supplier is 0

We start inventory with 0 units

our planning scope is infinite

ct how much do I have to pay every time we make an order

ce cost of maintaining every unit inside of the warehouse

d/q number of times we are asking units a year

q/2 average stock

Alright, so imagine you have a favorite snack that you eat every day. The Economic Order Quantity (EOQ) is like figuring out the best amount of that snack to buy each time so you don't run out or have too much left over.

Here's how it works:

You know how much of the snack you eat every day (D).

You decide how many snacks to buy each time (Q).

Every time you buy snacks, you have to pay a cost (Ct).

There's a cost for keeping snacks in your pantry each day (h).

When you order more snacks, they arrive instantly (delivery time is 0).

You start with no snacks in your pantry.

You plan to keep buying snacks like this forever.

By using the EOQ formula, you can find the perfect amount of snacks to buy each time so you save money on ordering costs and storage costs. It helps you make sure you always have enough snacks without wasting money on too many extras.

average inventory: Q/2

EOQ implies that we receive the inventory immediately so we should not wait any longer or I can ask as much as I want in case of an emergency

formulate it:

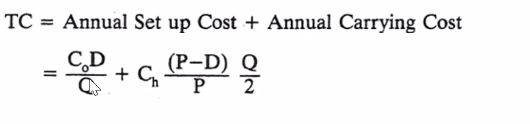

CT=the cost of the procurement+order cost+ maintain cost + stock out cost

TC(Q)=cD + cᵗ(D/Q) + Cₑ(Q/2)+cˢE[Units Short]

TRC total relevant cost(Q)=cᵗ(D/Q) + Cₑ(Q/2)

cuando el eoq llega al mínimo local (punto mínimo, mínimo óptimo): en términos de costo cuando el costo de ordenar y el costo de mantener son iguales

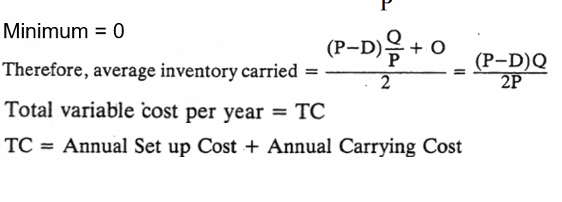

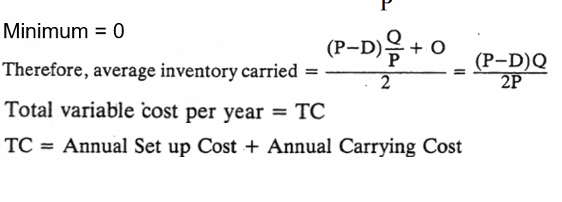

production model /modelo de produccion

imagine you are producing something and at the same time you are selling it

production time t1=q/ p

cycle time t2= q/ 2

so the maximum is: (P-D)xt1= (P-D)Q/P

Minimum = 0

set up cost: tiempo de preparación (por ejemplo de una maquina, de prender el horno)

por que al reducirse el costo del set up,…..: como cuesta menos poner la maquina, puedes producir mas cantidad de veces

por que al reducirse el costo del set up,…..: como cuesta menos poner la maquina, puedes producir mas cantidad de veces

Discount Model

when items are purchased in a bulk some discount is offered

Pros:

lower unit price

lower ordering cost

cheaper transportation

fewer stock-out

mass display by retailers

preferential treatment by sellers

Cons:

higher carrying costs

older stocks

lower-stock turnover

more capital requires

less flexibility

heavier deterioration and depreciation

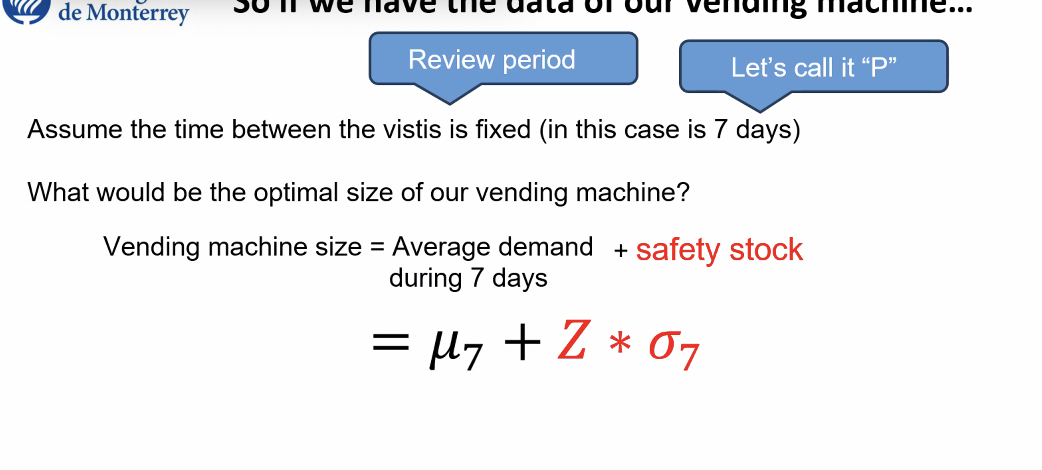

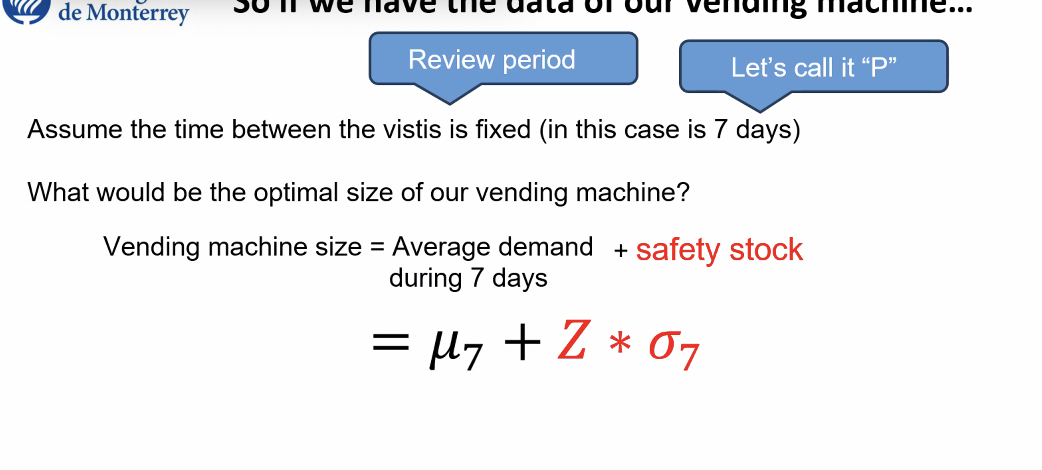

periodic review model (P)

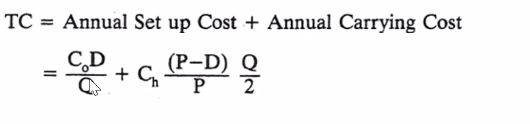

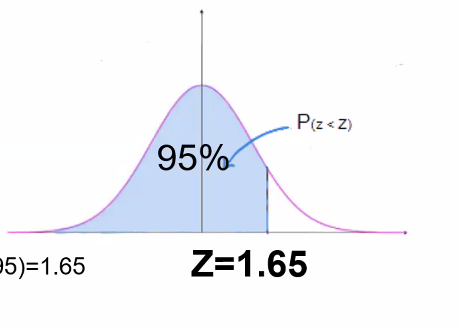

customer service level (novel de Servicio al cliente): probability to cover the demand during el periods de reabastecimiento

an external definition

based on the assumption that the demand has a normal distribution

Galton: la evolución existe si hay un shock en todo el ambiente y afecta a todas las especies, anda evoluciona de forma independiente sin ayuda externa

safety stock: depends 2 factors

customer service level

95% cantidad de datos que se encuentran en una distribución normal

95% cantidad de datos que se encuentran en una distribución normal

la desviación x la z es cuanto mas necesito

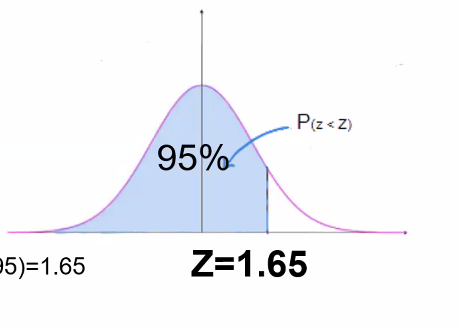

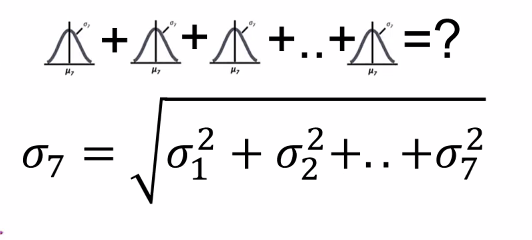

standard deviation during the 7 days

safety stock: z*deviacion7

safety stock: z*deviacion7

assuming that the daily demand is independent

assuming that the daily demand is independent

select the time between reviews P

Number of order= total demand / EOQ

P=1/number of orders

our target level is T=average demand +safety stock

characteristics of forecasts

forecasts are usually (always) wrong because of the random factor

they must be accompanied

forecasting techniques

Time series analysis: Analyzing historical data to identify patterns and make predictions.

Regression analysis: Examining relationships between variables to forecast future outcomes.

Qualitative techniques: Expert judgment and market research for valuable insights into future trends.

promedio movil (movil average 3, MA3): forma de revisar el error - MAPE.

reorder point EOQ

the quantity on hand plus the quantity ordered must last until next order is received

T=D(R+L)+SS

T: target level of inventory

D : is a function of the demand per unit per time

R: review period

L: lead time

SS: safety stock

ROP= reorder point is the level of the inventory which triggers an action to replenishment that item

The origin of MRP

BOM: bill of materials

MRP

rigid MRP schedule

slow between schedules

centralised

structured to support complex BOM

forecast driven

infinite capacity

complex

warehouse planning is a sub-complex of factory planning

WMS (warehouse management system): systems that tells us about everything in the warehouse, it covers a lot of things. control the inventory.

Advantages:

productivity

reduction of administrative work

job reduction

optimization of physical resources

Most common problems:

coverage

obsolescence

sku: stock keeping unit

The quantity on hand plus the quantity ordered must last until next order is received:

T (target level of inventory) = D (is a function of the demand per unit per time] (R [Review Period]+L [Lead time]) + SS [Safety Stock]

ROP = reorder point is the level of the inventory which triggers an action to replenish that item

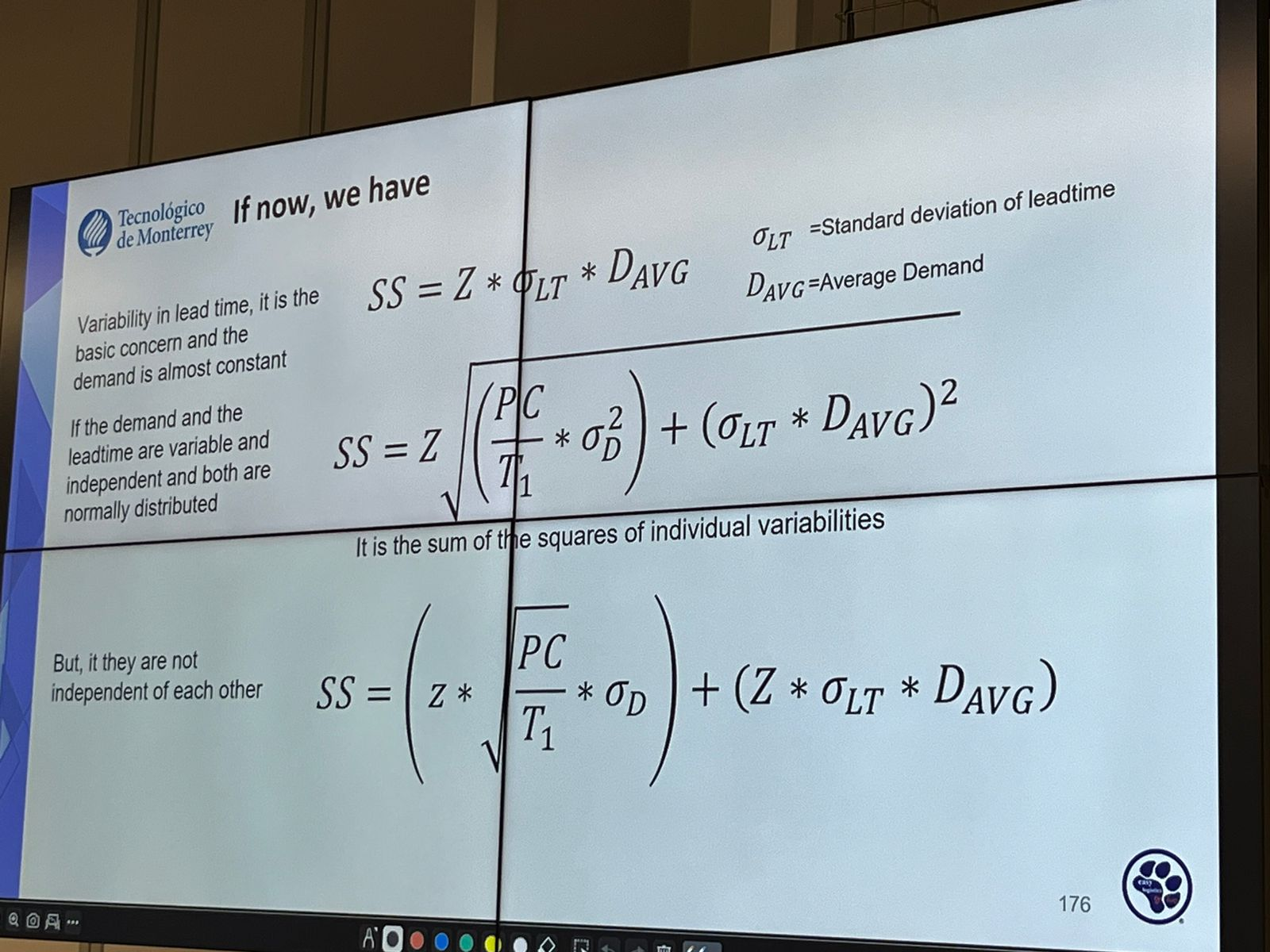

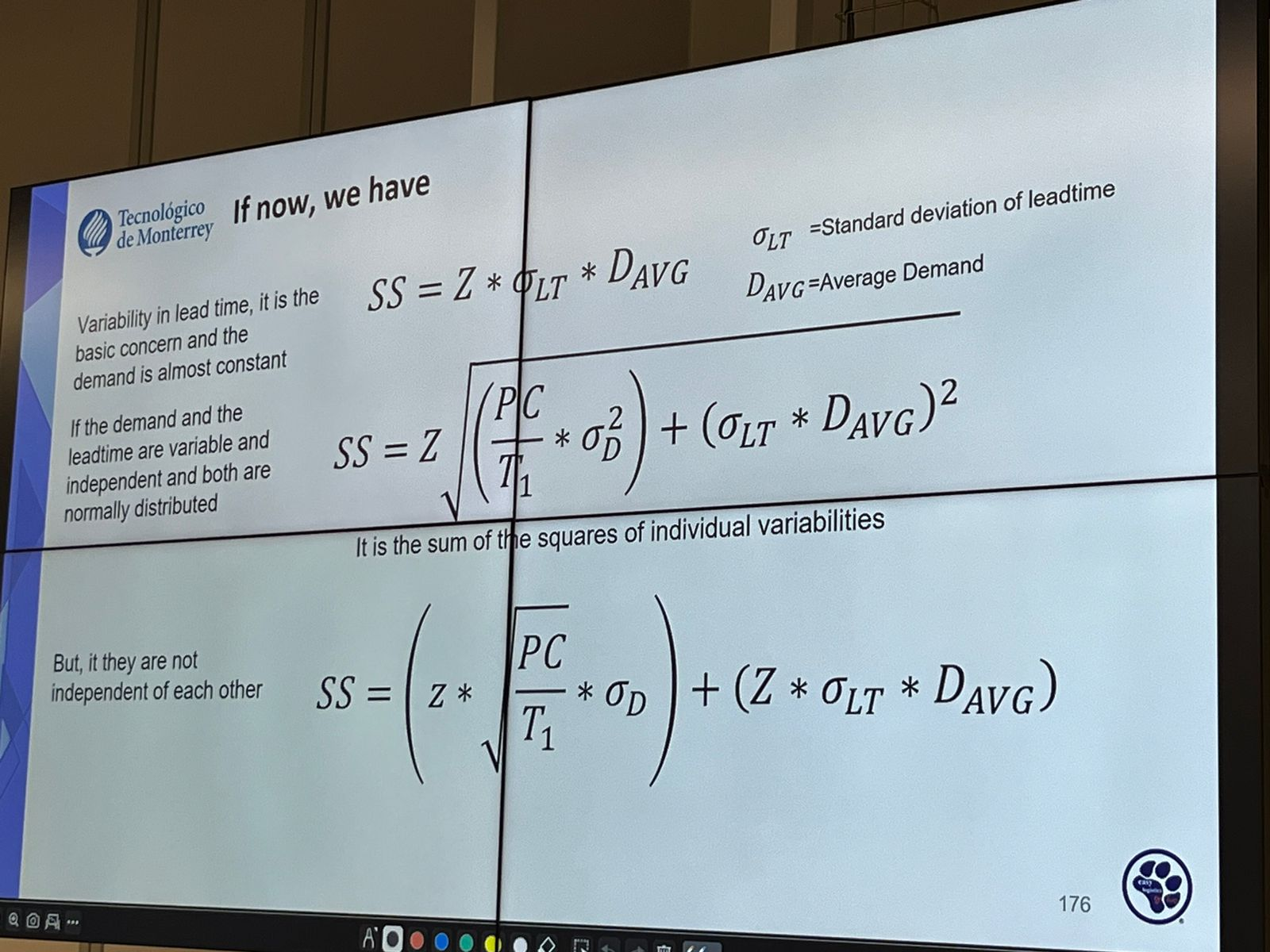

SS=Z*StandardDev*Raiz(LT)

SS = Z * StandardDevLeadTime * Average Demand

Just in Time (JIT) Inventory Technique

Definition: JIT is a management strategy that aims to increase efficiency and reduce waste by receiving goods only as they are needed in the production process.

Key Principles:

Minimize Inventory: Companies keep minimal inventory levels to avoid overstocking.

Continuous Flow: Products move through the production process without delays.

Quality Control: Emphasis on maintaining high-quality standards to prevent defects.

Benefits:

Cost Reduction: Lower inventory holding costs and reduced waste.

Improved Efficiency: Streamlined production process and reduced lead times.

Enhanced Flexibility: Allows for quick response to changes in demand.

Challenges:

Supply Chain Risks: Dependency on suppliers for timely deliveries.

Demand Variability: Fluctuations in demand can disrupt production schedules.

Quality Control: Requires strict quality standards to prevent disruptions.

Examples:

Toyota Production System: Pioneered the use of JIT in manufacturing.

Retail Industry: Some retailers use JIT to restock inventory based on real-time sales data.

Conclusion: JIT inventory technique is a lean approach that focuses on efficiency, cost reduction, and quality control by minimizing inventory levels and optimizing production processes.

Warehouse Management System

Increase in real warehouse capacityy

Stok in real time

Reliable location control Safety stock reduction

reluable management information

Infromation reluability improved customer service

Most common troubleshooting problems

Coverage

Obsolecense

Flag Driven Systems

Software only as flexible as the permutations of the switches

You model your business around the software

Process Driven Solutions

Receiving Processes

ASN Receipt

PO Receipt

Manufacturing receipt

Unknown receipt

Numerous options w/in process

Damages

UOMs

Harvest Unique Attributes

Putaway

QA

Damaged

Return to vendor

Repacking

Concentration

Pack and Hold

Top off Replenishment

Yard Staying

Crossdock

Receiving process

ASN receipt: aviso anticipado de embarque. pase rápido en aduana.

PO receipt:

manufacturing receipt:

unknown receipt:

numerous options w/in process:

damages

UOMs

Harvest Unique attributes

picking options

CEDIS: the value added services

LP: license plate, logistic unit inside the warehouse, todo lo q tanga código de barras

replenishment

loading: load auditing, system or user directed loading

inventory control - cycle count

auto generated w/ discrepancies

abc counts - velocity counts

planned-many methods

checks versus counts

opportunistic

full physicals

TMS: administrador de rutas de entrega

Fernando Frías

7 hits in logistics:

the right product

in the right amount

in the right place

at the right time

under the right conditions

at the right cost

to the right customer

Supply Chain

supply chain: global network used to deliver products and services from raw materials to end customers through the flow of information, physical distribution and cash. supply chain flows: product, money, information, energy.

A supply chain is like a big team that works together to get products and services from the very beginning to the people who want to buy them. It's like a long journey that involves different steps and lots of different things moving around.

Imagine you want to buy a toy. Before you can play with it, the toy needs to be made. The supply chain starts with getting the raw materials, like plastic and metal, to make the toy. These materials are then sent to a factory where the toy is put together.

Once the toy is made, it needs to be sent to the store where you can buy it. This is called the physical distribution part of the supply chain. The toy might travel on a truck, a ship, or even an airplane to reach the store.

But that's not all! Along the way, there are other important things that need to flow through the supply chain. One of them is information. This means that everyone involved in making and delivering the toy needs to know what's happening. They need to know how many toys are being made, where they are going, and when they will arrive at the store.

Another important thing that flows through the supply chain is money. The people who make the toy and transport it need to get paid, right? So, money needs to move from the store to the factory and all the other places involved.

Lastly, energy is also part of the supply chain. Think about the fuel needed to power the trucks, ships, and airplanes that transport the toy. Without energy, the toy wouldn't be able to make its way to the store.

So, in summary, a supply chain is like a big team that works together to get products and services to you. It involves the flow of products, money, information, and energy. Each step is important to make sure everything gets to where it needs to go.

Value Chain

value chain: it comprises the functions within a company that add value to the goods or services that the organization sells to customers and for which it receives payment.

Imagine you have a lemonade stand. You start with lemons, sugar, and water, and you turn them into delicious lemonade. Then, you sell the lemonade to your customers and they give you money in return.

Now, think of a big company like a toy factory. They have many different steps, or functions, to make and sell their toys. The value chain is like a series of steps that add value to the toys and help the company make money.

First, the toy factory needs to design the toys. They come up with cool ideas and draw pictures of what the toys will look like. This is the first step in the value chain.

Next, they need to buy the materials to make the toys. They get things like plastic, paint, and batteries. These materials are used to actually create the toys. This is the second step.

After that, the factory workers start making the toys. They use machines and tools to shape the plastic, paint the toys, and put in the batteries. This is the third step.

Once the toys are made, they need to be packaged. The factory workers put the toys in boxes and add labels and instructions. This is the fourth step.

Now, the toys are ready to be sent to stores. The factory ships the toys to different stores around the world. This is the fifth step.

Finally, the stores sell the toys to customers. People come to the stores, see the toys, and decide to buy them. The stores make money from selling the toys. This is the last step in the value chain.

So, the value chain is all the steps a company goes through to add value to their products and make money. Each step is important because it helps create a product that customers want to buy.

logistics

moving one product from point a to point b, moving from point b to point c. It is the functional point that provides for the physical movement of items between raw materials, factories, warehouses and customers.

the base of everything is the customer because it has a need, wants to pay (cost), knowledge (you gotta know how to pay, como entrar para atacar la necesidad), and convenience. 4p´s.

take control of the inventory or you´ll lose money.

Logistics is like a big game of moving things from one place to another. Imagine you have a toy car that you want to send to your friend who lives far away. First, you need to get the toy car from your house (point A) to the post office (point B). Then, the post office needs to send it to your friend's house (point C).

Logistics is all about making sure this process happens smoothly. It involves moving things like raw materials (the stuff that makes the toy car), the toy car itself, and even other products that people want to buy.

The most important part of logistics is the customer. The customer is the person who wants to buy or receive the product. They have a need or want for the product, they are willing to pay for it, they know how to pay for it, and they want it to be convenient. These are called the 4 P's: need, payment, knowledge, and convenience.

So, logistics is like a big puzzle where we figure out how to move things from one place to another, making sure the customer gets what they need in a way that is easy for them.

compra post distribuida

la compra ya viene surtida por tienda.

La compra post distribuida es cuando compras algo y la tienda ya tiene todo listo para ti. Imagina que quieres comprar comida en el supermercado, pero en lugar de tener que ir a buscar cada producto en los estantes, la tienda ya ha recogido todos los productos que necesitas y los ha puesto juntos en un solo lugar. Así, cuando llegas a la tienda, solo tienes que recoger tu compra y pagar en la caja. Es como si alguien hubiera hecho la compra por ti y solo tienes que recogerla. Esto puede ser muy conveniente porque ahorra tiempo y esfuerzo.

principles of inventory and warehousing

variations: delays or incomplete delivery, demand changes, seasonality, spot orders.

restrictions: purchase minimums, lead time(time the supplier takes to deliver the product), quotas (like a condition), review periods (you make your order today but the orders are only on mondays), warehouse capacity, cash flow, product useful life.

Inventory and warehousing are important concepts in managing products and making sure they are available when people want to buy them. Let's break it down!

Inventory is like a big collection of things that a company has to sell. It can be things like toys, clothes, or even food. When a company has a lot of inventory, it means they have a lot of things to sell. But having too much inventory can be a problem because it costs money to store and manage all those things.

Warehousing is like a big storage place where companies keep their inventory. It's like a giant closet or a big warehouse building. Warehouses have shelves and racks to organize the inventory and make it easy to find things when they are needed.

Now, let's talk about some important principles of inventory and warehousing:

Delays or Incomplete Delivery: Sometimes, the things that a company orders may not arrive on time or may not be complete. This can cause problems because the company may not have enough inventory to sell to customers.

Demand Changes: The amount of things that people want to buy can change over time. For example, during the holiday season, people may want to buy more toys. Companies need to be prepared for these changes in demand and have enough inventory to meet the needs of their customers.

Seasonality: Some products are more popular during certain times of the year. For example, swimsuits are more popular in the summer. Companies need to plan their inventory and warehousing based on these seasonal changes in demand.

Spot Orders: Sometimes, companies may need to order more inventory quickly to meet unexpected demand. These are called spot orders. Warehousing needs to have enough space to store these extra items until they are sold.

There are also some restrictions that companies need to consider when managing their inventory and warehousing:

Purchase Minimums: Some suppliers may have a minimum quantity that a company needs to order. This means that the company cannot order just a few items, they have to order a certain amount.

Lead Time: Lead time is the time it takes for the supplier to deliver the ordered products. Companies need to plan their inventory and warehousing based on this lead time to make sure they have enough inventory when they need it.

Quotas: Quotas are like conditions that suppliers may have. For example, a supplier may only allow a company to order a certain

warehouse process

reception - putaway - packaging - shipping - control.

Sure! Imagine you have a big warehouse where you store lots of things like toys, clothes, and books. There are different steps that happen in the warehouse to make sure everything is organized and ready to be sent to people who want to buy them. Let's break down the process into five simple steps:

Reception: This is where all the new things arrive at the warehouse. Just like when you receive a package at home, the warehouse workers receive the items and check if everything is there and in good condition. They make a list of what they received.

Putaway: After the items are checked, they need to be put in the right place in the warehouse. It's like when you clean your room and put your toys back in their proper places. Warehouse workers find a spot for each item so they can easily find it later when someone wants to buy it. (a veces se depends del operator pq la pone en donde sea)

quality assurance: that it is okay

damage: if there is damage you send it to other options or you return it (take a photo, a document, send emails)

Packaging: When someone buys something from the warehouse, the workers need to pack it up nicely and safely. They put the item in a box or a bag and make sure it's protected so it doesn't get damaged during shipping. It's like when you wrap a gift for your friend's birthday.

concentration

pack and hold: you are going to send it later

top off replenishment

yard staying

Shipping: This is when the packed items are ready to leave the warehouse and go to their new owners. The warehouse workers put the packages on trucks or planes to send them to different places. It's like when you give a letter to the mailman to send it to your grandma who lives far away.

Control: This step is important to make sure everything is going smoothly. The warehouse workers keep track of what items are coming in and going out. They check if any mistakes were made and fix them. It's like when you double-check your homework to make sure you didn't make any errors.

So, the warehouse process goes like this: First, the items are received and checked. Then, they are put in the right place in the warehouse. After that, the items are packed nicely for shipping. Next, they are sent out to their new owners. Finally, the workers keep an eye on everything to make sure it's all going well.

ERP (enterprise resource planning) software

system that controls the company total. accounting(internal), finance(external), hr, procurement (items, suppliers, po´s), sales.

ERP (Enterprise Resource Planning) Software

Imagine you have a big company with lots of different departments like accounting, finance, human resources, procurement, and sales. Each department has its own important tasks and information. But it can be really hard to keep track of everything and make sure everyone is working together smoothly.

That's where ERP software comes in! ERP stands for Enterprise Resource Planning. It's like a super smart computer program that helps manage and control all the different parts of a company. It's like the boss of the company's computer system!

ERP software helps the company keep track of its money, like how much it's spending and how much it's making. It also helps with things like paying employees and keeping track of important financial information.

But ERP software doesn't just help with money stuff. It also helps with other important things like managing employees and their information, like their names, addresses, and job titles. It helps with buying things the company needs, like supplies or equipment, by keeping track of what's in stock and when to order more. It even helps with selling things by keeping track of customers and orders.

So basically, ERP software is like a big computer program that helps a company manage and control all the different parts of its business. It keeps everything organized and makes sure everyone is working together smoothly. It's like having a super smart assistant that helps the company run smoothly and be successful!

WMS: warehouse management system.

A warehouse management system, or WMS for short, is like a super smart computer program that helps people manage and organize things in a big warehouse. Imagine a huge storehouse filled with all kinds of items like toys, clothes, and food. It can be really hard to keep track of where everything is and make sure things are stored properly. That's where a WMS comes in!

Think of a WMS as a boss that tells workers where to put things and keeps track of what's in the warehouse. It uses special technology like barcodes or radio frequency identification (RFID) to keep tabs on all the items. When something new comes into the warehouse, the WMS gives it a special code and tells the workers where to put it. This way, everything has its own special spot and it's easy to find later.

But that's not all! The WMS also helps with other important tasks. It can tell workers when it's time to restock items that are running low, so the store never runs out of things to sell. It can also help plan the best way to move items around the warehouse, so workers don't waste time and energy. Plus, it can keep track of important information like how many items are sold each day, so the store knows what's popular and what's not.

In summary, a warehouse management system is like a super smart computer program that helps people keep track of and organize things in a big warehouse. It tells workers where to put things, keeps track of what's in the warehouse, helps restock items, and makes sure everything runs smoothly.

Warehouse control system

A warehouse control system (WCS) is a software application that manages and controls the operations within a warehouse. It is responsible for directing the flow of work within the warehouse, optimizing processes, and ensuring efficient use of resources. WCS works in conjunction with warehouse management systems (WMS) to coordinate tasks such as picking, packing, and shipping of goods. One key feature of WCS is its ability to communicate with automated material handling equipment, such as conveyor systems, sorters, and robots, to ensure smooth and accurate movement of goods throughout the warehouse. By integrating with various technologies and systems, WCS helps improve warehouse efficiency, accuracy, and productivity. Overall, a well-implemented WCS plays a crucial role in streamlining warehouse operations and enhancing overall supply chain performance.

operation flow of a warehouse (it determines the bases of the logistics and operational capabilities)

suppliers - reception - putaway - picking - shipping - customers

Sure! Imagine a warehouse as a big storehouse where things are stored and organized. The operation flow of a warehouse is like a step-by-step process that helps keep everything running smoothly.

Suppliers: The first step is when suppliers bring in the products to the warehouse. Suppliers are like the people who bring groceries to a store.

Reception: Once the products arrive, the warehouse workers check and count them to make sure everything is correct. It's like when you go to a store and the cashier checks the items you want to buy.

Putaway: After the products are checked, they need to be put away in the right place. Warehouse workers organize the products on shelves or in designated areas. It's like when you put your toys back in their proper places after playing with them.

Picking: When a customer places an order, warehouse workers go to the shelves and pick the items that the customer wants. It's like when you ask your mom to get you a specific toy from your toy box.

Shipping: Once the items are picked, they are packed securely in boxes or packages. Then, they are sent out for delivery to the customers. It's like when you put your toy in a box and give it to the mailman to send it to your friend.

Customers: Finally, the customers receive the products they ordered and are happy! They can use or enjoy the items they received. It's like when you receive a package in the mail and open it to find a new toy to play with.

So, the operation flow of a warehouse goes from suppliers bringing in products, to reception and checking, then organizing and storing the products, picking the items for orders, shipping them out, and finally, the customers receiving and enjoying their purchases.

Sales and Operations Planning

aggregated planning, capacity management and its restrictions in different time horizons,

Types of enterprises:

Retail: Walmart, Soriana

Industry

Services: consultancy

Projects

Public

Sales and Operations Planning (S&OP) is a way for businesses to plan and manage their activities. It helps them make decisions about how much to produce, how much to sell, and how to use their resources effectively.

Imagine you have a lemonade stand. You need to plan how many lemons, sugar, and cups to buy, and how much lemonade to make each day. S&OP is like that, but for bigger businesses.

S&OP involves different types of planning. One is aggregated planning, which means looking at the big picture and making plans for the whole business. For example, Walmart plans how much stuff to buy for all its stores across the country.

Another part of S&OP is capacity management. This means figuring out how much the business can produce or provide. For example, a factory needs to know how many cars it can make in a month.

But there are restrictions too. Sometimes, businesses can't produce as much as they want because of limitations. For example, a factory might not have enough workers or machines to make more cars.

S&OP also looks at different time horizons. This means planning for different periods of time. For example, a retail store like Walmart plans for the whole year, while a factory might plan for just a month.

There are different types of enterprises that use S&OP. Retail businesses like Walmart and Soriana use it to plan how much stuff to buy and sell in their stores. Industries use it to plan how much to produce and manage their resources. Service businesses like consultancies use it to plan their projects and allocate their resources. Public organizations also use it to plan their activities and manage their resources.

In summary, Sales and Operations Planning is a way for businesses to plan and manage their activities. It involves looking at the big picture, managing resources, and making decisions about what to produce and sell. Different types of businesses use it to plan for different time periods and manage their operations effectively.

Product life cycle

The product life cycle is like the journey of a product from when it is first made to when it is no longer used or sold. It has four main stages: introduction, growth, maturity, and decline.

Introduction: This is when a new product is introduced to the market. It's like when a new toy comes out and everyone wants to try it. Companies spend a lot of time and money to make people aware of the product and convince them to buy it.

Growth: Once people start buying the product, it enters the growth stage. It's like when the toy becomes really popular and everyone wants to have it. The company starts making more of the product to meet the demand, and they may even make improvements to make it better.

Maturity: After a while, the product reaches the maturity stage. It's like when the toy is not as exciting anymore because everyone already has it. Sales may start to slow down, but the product is still being sold. Companies may lower the price or offer special deals to keep people interested.

Decline: Eventually, the product enters the decline stage. It's like when the toy is no longer popular and people are not buying it as much. The company may decide to stop making the product or replace it with something new and better.

So, the product life cycle is all about how a product goes through different stages, from being new and exciting to becoming less popular and eventually being replaced.

Demand types:

Dependent demand:

derives from the need to assemble or manufacture a product and is generated according to the structure of a product, they are the component parts, sub assembles and raw materials which are necessary for the finished product and manufacturing

Dependent demand is when we need certain things to make a product. These things can be parts, smaller pieces, or even raw materials. They are all necessary to put together the finished product. So, if we want to make a toy car, we need wheels, a body, and other parts. These parts are dependent on each other because we can't make the toy car without them. It's like building with Lego blocks - we need all the different pieces to make the final creation. The demand for these parts and materials is based on how many finished products we want to make. So, if we want to make 10 toy cars, we need 40 wheels, 10 bodies, and all the other parts that go into making them. Dependent demand helps us plan and organize the manufacturing process so that we have everything we need to make the products efficiently.

Independent Demand:

generated directly from customers need, finished product or a spare part that is requested for sale directly in a customer and is billed in a product sale.

Imagine you have a toy store, and you sell all kinds of toys to kids. Sometimes, kids come to your store and ask for a specific toy they want to buy. This is called independent demand.

Independent demand is when customers directly ask for a particular product or spare part that they want to buy. It could be a finished product, like a toy or a game, or it could be a spare part for something they already have, like a missing puzzle piece or a broken toy part.

When customers ask for these things, you sell them the product they want, and they pay you for it. You then give them a bill, which is like a receipt that shows how much they need to pay for the product.

So, independent demand is all about customers needing and asking for specific things that they want to buy directly from you. It's different from other types of demand, like when you decide to make more toys to sell in your store without anyone asking for them.

Remember, independent demand is when customers generate the need for a product, and you sell it to them directly.

push vs pull process

push: anticipates demand, implies forecasting, proactive process

pull:it is a response to a work order the demand is known and real

Push and Pull in a Simple Way

Push and pull are two different ways of doing things, especially when it comes to getting work done or making products. Let's imagine we are talking about making yummy cupcakes!

Push: Anticipating Demand

Push is like when you make a lot of cupcakes even before anyone asks for them. It's like you are guessing that people will want cupcakes, so you make a bunch in advance. This is called "anticipating demand" or "forecasting." It's a proactive process because you are taking action before knowing for sure if people will actually want the cupcakes.

Pull: Responding to Demand

Pull, on the other hand, is when you make cupcakes only when someone asks for them. It's like you have a special order from someone who really wants cupcakes, so you make them specifically for that person. In this case, the demand is known and real because someone has already asked for the cupcakes.

So, push is about making things before people ask for them, while pull is about making things when people actually want them. Both ways have their own advantages and are used in different situations. It's like having different tools in your toolbox and using the right one for the job!

Remember, push is like guessing what people want and making things in advance, while pull is about making things when someone asks for them.

Order Management

management of various activities associated with the order cycle. This process consists in 4 parts.

order transmittal:

order processing: refers to the time when the seller receives the order until a location (warehouse) is authorized to fill the order

order picking and assembly: all activities from when the warehouse is authorized to fill the order until goods are loaded on board an outbound carrier.

order delivery: is the final phase of order cycle and refers to the time when a transportation carrier picks up the shipment until it is received by the customer.

Supply planning schemes

Past: based on historical behavior based on descriptive statistical data, future will behave like the past, risk of not being aware of what will happen in the future

present

future: based on a forecast of independent or dependent variables, based on quantitative or qualitative forecasting techniques, to anticipate what will happen in the future, risk of erring in the forecast

Supply Planning Schemes

In simple terms, supply planning schemes are ways to figure out how much of something we need in the future.

In the past, people used to look at how things happened before to guess what will happen in the future. They looked at numbers and facts to make predictions. But sometimes, things can change and we might not know what will happen next. This is a risk because we might not be prepared for what's coming.

Nowadays, we have better ways to plan for the future. We use a forecast, which is like a guess, to predict what will happen. We look at different things that can affect the future, like how many people want to buy something or how much money people have. We can use numbers or even people's opinions to make these predictions.

But there's a risk with this too. Sometimes, our guess can be wrong and we might plan for too much or too little of something. This can cause problems because we might not have enough of what people want or we might have too much and waste it.

So, supply planning schemes are ways to help us plan for the future by looking at what happened before or making educated guesses. But we always need to be careful because we can't be 100% sure about what will happen.

Forecast

process that allows estimating what will happen in the future. there are various methods.

4 characteristics: are usually (always) wrong because of the random factor, they must be accompanied by a measure of error, the forecast error measure (standard deviation) quantifies the degree of confidence in the forecast, aggregate forecasts are more accurate than detailed forecasts. summarization reduces variability, in the longer term it is the less certain prognosis. with better info, a better prediction is made.

Forecast

A forecast is like predicting what will happen in the future. It's a way to estimate or guess what might happen based on information we have. There are different ways to make forecasts.

Here are four important things to know about forecasts:

Forecasts are usually not 100% accurate because there are random things that can happen and change the outcome. So, it's like making a guess, but we know it might not be exactly right.

When we make a forecast, we also need to say how confident we are in that guess. We do this by using something called a forecast error measure, which tells us how much we might be off by. It's like saying, "I think it will be sunny tomorrow, but there's a chance it might rain."

When we make forecasts for a big group of things together, like a whole city or country, they tend to be more accurate than when we try to predict specific details for each thing. It's like if we try to guess how many candies each person will eat at a party, it's harder to be right for each person, but easier to guess the total number of candies everyone will eat.

Forecasts become less certain the further into the future we try to predict. It's easier to guess what might happen tomorrow than what might happen in a year. But if we have more information, like weather patterns or trends, we can make better predictions.

So, a forecast is like making an educated guess about what might happen in the future, but we know it might not be exactly right because of random things that can happen. The more information we have and the bigger the group we're predicting for, the better our forecast can be.

What can be predicted are classified in 2 events

repeating events: they occur and will occur naturally and persistently over time. we can analyze their regularity based on their trend and seasonality to be able to anticipate their evolution in the future.

extraordinary events: they occur completely unforeseen and we do not have a good enough chance of estimating their occurrence in the future.

Understanding the inventory logic

Assumptions EOQ (economic order quantity)

The demand is a daily constant (D)

We all time ask the time quantity (Q)

every time we order, we pay cost (Ct)

The cost to keep stock per day is (h) per each SKU

The delivery time from the supplier is 0

We start inventory with 0 units

our planning scope is infinite

ct how much do I have to pay every time we make an order

ce cost of maintaining every unit inside of the warehouse

d/q number of times we are asking units a year

q/2 average stock

Alright, so imagine you have a favorite snack that you eat every day. The Economic Order Quantity (EOQ) is like figuring out the best amount of that snack to buy each time so you don't run out or have too much left over.

Here's how it works:

You know how much of the snack you eat every day (D).

You decide how many snacks to buy each time (Q).

Every time you buy snacks, you have to pay a cost (Ct).

There's a cost for keeping snacks in your pantry each day (h).

When you order more snacks, they arrive instantly (delivery time is 0).

You start with no snacks in your pantry.

You plan to keep buying snacks like this forever.

By using the EOQ formula, you can find the perfect amount of snacks to buy each time so you save money on ordering costs and storage costs. It helps you make sure you always have enough snacks without wasting money on too many extras.

average inventory: Q/2

EOQ implies that we receive the inventory immediately so we should not wait any longer or I can ask as much as I want in case of an emergency

formulate it:

CT=the cost of the procurement+order cost+ maintain cost + stock out cost

TC(Q)=cD + cᵗ(D/Q) + Cₑ(Q/2)+cˢE[Units Short]

TRC total relevant cost(Q)=cᵗ(D/Q) + Cₑ(Q/2)

cuando el eoq llega al mínimo local (punto mínimo, mínimo óptimo): en términos de costo cuando el costo de ordenar y el costo de mantener son iguales

production model /modelo de produccion

imagine you are producing something and at the same time you are selling it

production time t1=q/ p

cycle time t2= q/ 2

so the maximum is: (P-D)xt1= (P-D)Q/P

Minimum = 0

set up cost: tiempo de preparación (por ejemplo de una maquina, de prender el horno)

por que al reducirse el costo del set up,…..: como cuesta menos poner la maquina, puedes producir mas cantidad de veces

por que al reducirse el costo del set up,…..: como cuesta menos poner la maquina, puedes producir mas cantidad de veces

Discount Model

when items are purchased in a bulk some discount is offered

Pros:

lower unit price

lower ordering cost

cheaper transportation

fewer stock-out

mass display by retailers

preferential treatment by sellers

Cons:

higher carrying costs

older stocks

lower-stock turnover

more capital requires

less flexibility

heavier deterioration and depreciation

periodic review model (P)

customer service level (novel de Servicio al cliente): probability to cover the demand during el periods de reabastecimiento

an external definition

based on the assumption that the demand has a normal distribution

Galton: la evolución existe si hay un shock en todo el ambiente y afecta a todas las especies, anda evoluciona de forma independiente sin ayuda externa

safety stock: depends 2 factors

customer service level

95% cantidad de datos que se encuentran en una distribución normal

95% cantidad de datos que se encuentran en una distribución normal

la desviación x la z es cuanto mas necesito

standard deviation during the 7 days

safety stock: z*deviacion7

safety stock: z*deviacion7

assuming that the daily demand is independent

assuming that the daily demand is independent

select the time between reviews P

Number of order= total demand / EOQ

P=1/number of orders

our target level is T=average demand +safety stock

characteristics of forecasts

forecasts are usually (always) wrong because of the random factor

they must be accompanied

forecasting techniques

Time series analysis: Analyzing historical data to identify patterns and make predictions.

Regression analysis: Examining relationships between variables to forecast future outcomes.

Qualitative techniques: Expert judgment and market research for valuable insights into future trends.

promedio movil (movil average 3, MA3): forma de revisar el error - MAPE.

reorder point EOQ

the quantity on hand plus the quantity ordered must last until next order is received

T=D(R+L)+SS

T: target level of inventory

D : is a function of the demand per unit per time

R: review period

L: lead time

SS: safety stock

ROP= reorder point is the level of the inventory which triggers an action to replenishment that item

The origin of MRP

BOM: bill of materials

MRP

rigid MRP schedule

slow between schedules

centralised

structured to support complex BOM

forecast driven

infinite capacity

complex

warehouse planning is a sub-complex of factory planning

WMS (warehouse management system): systems that tells us about everything in the warehouse, it covers a lot of things. control the inventory.

Advantages:

productivity

reduction of administrative work

job reduction

optimization of physical resources

Most common problems:

coverage

obsolescence

sku: stock keeping unit

The quantity on hand plus the quantity ordered must last until next order is received:

T (target level of inventory) = D (is a function of the demand per unit per time] (R [Review Period]+L [Lead time]) + SS [Safety Stock]

ROP = reorder point is the level of the inventory which triggers an action to replenish that item

SS=Z*StandardDev*Raiz(LT)

SS = Z * StandardDevLeadTime * Average Demand

Just in Time (JIT) Inventory Technique

Definition: JIT is a management strategy that aims to increase efficiency and reduce waste by receiving goods only as they are needed in the production process.

Key Principles:

Minimize Inventory: Companies keep minimal inventory levels to avoid overstocking.

Continuous Flow: Products move through the production process without delays.

Quality Control: Emphasis on maintaining high-quality standards to prevent defects.

Benefits:

Cost Reduction: Lower inventory holding costs and reduced waste.

Improved Efficiency: Streamlined production process and reduced lead times.

Enhanced Flexibility: Allows for quick response to changes in demand.

Challenges:

Supply Chain Risks: Dependency on suppliers for timely deliveries.

Demand Variability: Fluctuations in demand can disrupt production schedules.

Quality Control: Requires strict quality standards to prevent disruptions.

Examples:

Toyota Production System: Pioneered the use of JIT in manufacturing.

Retail Industry: Some retailers use JIT to restock inventory based on real-time sales data.

Conclusion: JIT inventory technique is a lean approach that focuses on efficiency, cost reduction, and quality control by minimizing inventory levels and optimizing production processes.

Warehouse Management System

Increase in real warehouse capacityy

Stok in real time

Reliable location control Safety stock reduction

reluable management information

Infromation reluability improved customer service

Most common troubleshooting problems

Coverage

Obsolecense

Flag Driven Systems

Software only as flexible as the permutations of the switches

You model your business around the software

Process Driven Solutions

Receiving Processes

ASN Receipt

PO Receipt

Manufacturing receipt

Unknown receipt

Numerous options w/in process

Damages

UOMs

Harvest Unique Attributes

Putaway

QA

Damaged

Return to vendor

Repacking

Concentration

Pack and Hold

Top off Replenishment

Yard Staying

Crossdock

Receiving process

ASN receipt: aviso anticipado de embarque. pase rápido en aduana.

PO receipt:

manufacturing receipt:

unknown receipt:

numerous options w/in process:

damages

UOMs

Harvest Unique attributes

picking options

CEDIS: the value added services

LP: license plate, logistic unit inside the warehouse, todo lo q tanga código de barras

replenishment

loading: load auditing, system or user directed loading

inventory control - cycle count

auto generated w/ discrepancies

abc counts - velocity counts

planned-many methods

checks versus counts

opportunistic

full physicals

TMS: administrador de rutas de entrega

Knowt

Knowt